Used Commercial Laundry Equipment: Costs, Risks, and Long-Term ROI

Table of Contents

Used commercial laundry equipment catches the attention of business owners wrestling with tight budgets and pressing deadlines. The prospect of saving thousands upfront makes perfect sense, particularly when respected brands like Speed Queen or Dexter still hold their value in the resale market. But after working with facilities across Colorado and Wyoming, Real Clean Group has seen how the choice between used and new equipment requires deeper analysis than just comparing price tags.

Experienced operators understand that commercial laundry equipment isn't just a purchase, it's a long-term operational investment. The right decision hinges on your facility's current state, service needs, parts availability, and what ownership will actually cost over 5-10 years.

TL;DR: The Real Cost of Used Commercial Laundry Equipment

Plenty of businesses eye used commercial washers and dryers to slash upfront spending. Those initial savings of 30-50% look great on paper, but hidden costs have a way of surfacing through higher utility bills, constant repairs, and surprise downtime. Modern ENERGY STAR certified commercial washers deliver 9% better energy efficiency and use 45% less water than older standard models. That efficiency gap adds up fast.

Key Points:

Shortened lifespan ahead - Frontload washers and dryers typically run 10-15 years when new, but used equipment usually offers just 2-5 years of remaining service

Maintenance headaches multiply - The Coin Laundry Association's 2024 survey found 34% of operators cite high maintenance costs as their biggest business challenge

Facility compatibility problems including outdated plumbing, electrical systems, and ventilation that can't handle older models properly

Warranty gaps since manufacturer coverage almost never transfers to second owners

Technology blind spots where you miss out on smart monitoring and efficiency tracking that modern equipment provide

Real Clean Group helps businesses cut through these tradeoffs objectively. Instead of pushing equipment sales, they work with operators to assess real operational costs, facility readiness, and performance requirements over time. Whether you end up choosing used, new, or some combination, having an experienced commercial laundry service partner keeps your systems running reliably for years

“If a machine can’t stay online, it can’t stay profitable. Reliability is the heart of every successful laundry operation.”

Why Businesses Consider Used Commercial Laundry Equipment

The attraction to used laundromat equipment starts with simple arithmetic. A refurbished Speed Queen washer runs $3,000-$5,000 versus $8,000-$12,000 for the same model brand new. For laundromats, apartment complexes, salons, or hotels starting operations with constrained budgets, these savings free up cash for marketing, staffing, or facility upgrades.

Keeping Capital Available

Used commercial washers for sale provide immediate financial breathing room while preserving capital for other priorities. A 10-machine laundromat could save $50,000-$70,000 going used instead of new.

But preserved capital only helps if operating costs don't eat away those savings. Equipment approaching the end of its normal lifespan needs replacement sooner, possibly within 2-5 years. That initial "savings" becomes more like a short-term loan against future expenses.

Brand Names Still Matter

Speed Queen refurbished units and used Dexter washers stay popular because these companies earned reputations for building tough machines. Equipment designed for nonstop commercial use should theoretically handle years of heavy operation.

Reality gets messier though. While Speed Queen and Maytag Commercial top reliability charts for new equipment, how well a used machine performs depends completely on maintenance history, usage patterns, and what's left in the tank. A poorly maintained Speed Queen can perform worse than a well-cared-for budget brand.

Getting Equipment Faster

New commercial equipment orders sometimes stretch 8-12 weeks, especially for custom configurations or during busy periods. Used commercial laundry equipment for sale near me searches often turn up inventory that's ready to go.

This convenience has hidden costs. Rushed purchases skip thorough facility assessments that check whether existing plumbing, electrical, and ventilation can actually support what you're buying. Installation problems discovered late drive up total project costs significantly.

Types of Used Commercial Laundry Equipment Available

The used commercial laundry equipment market serves up various options, each meeting specific needs while presenting unique evaluation challenges.

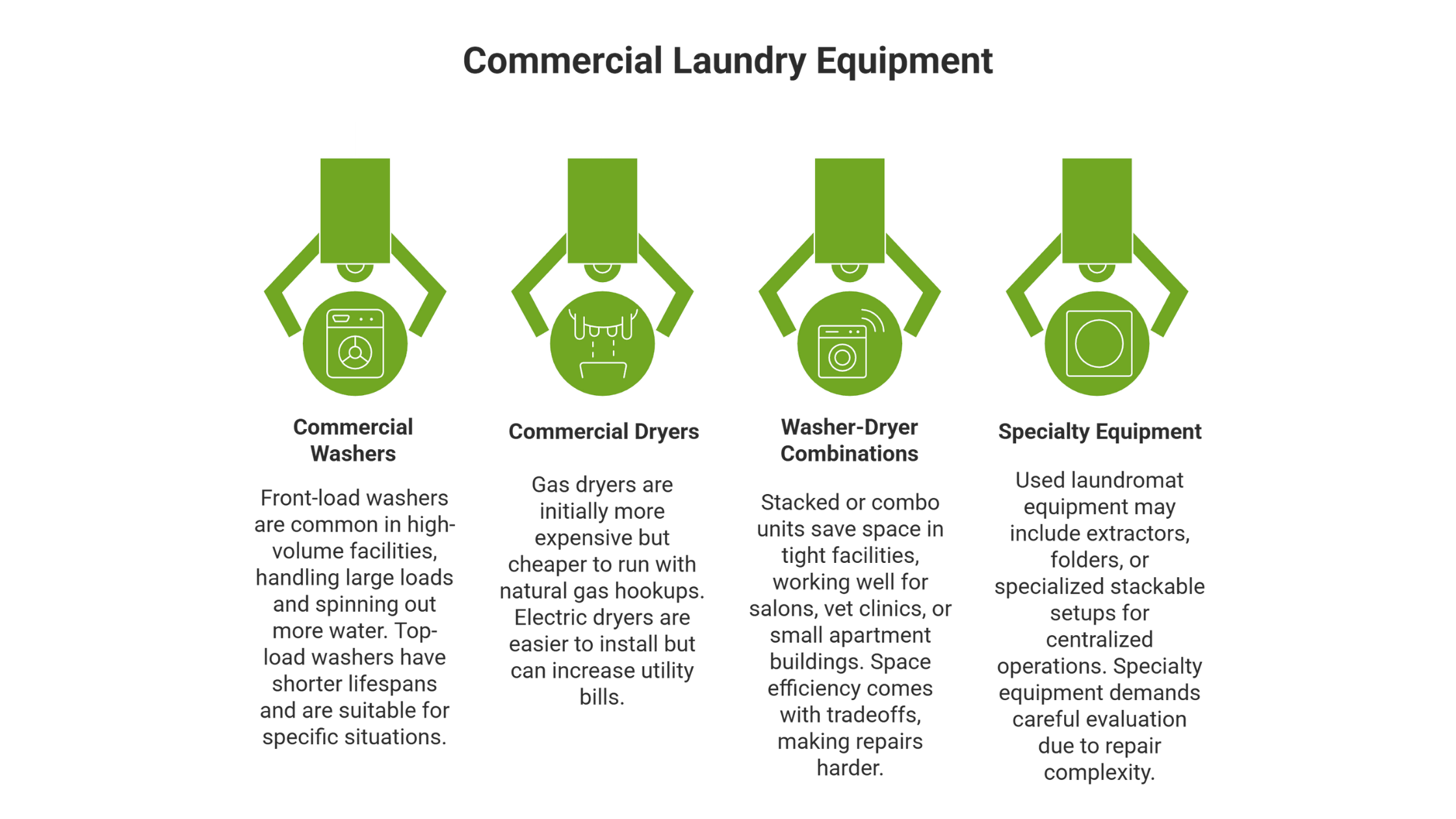

Commercial Washers (Front-Load and Top-Load)

Front-load commercial washers dominate used inventory because they're everywhere in high-volume facilities. These machines handle 20-75 pound loads and spin out more water, cutting dryer time. Used commercial washers for sale often come from hotels or hospitals upgrading after 7-10 years.

Top-load commercial washers have shorter lifespans of 5-8 years, so used top-load units don't offer much time left. They work for specific situations like correctional facilities or places that prefer faster loading cycles.

Commercial Dryers (Gas and Electric)

Used commercial dryers split between gas and electric power. Gas dryers cost more initially but run cheaper in facilities with natural gas hookups. Electric models install easier but might jack up utility bills in high-volume operations.

Older dryers miss modern efficiency features entirely. New equipment with inverter motors cuts energy use dramatically, while used commercial dryer units stick with older technology that burns substantially more per cycle.

Complete Washer-Dryer Combinations

Stacked or combo units solve space problems in tight facilities. Used commercial washer dryer combinations work well for salons, vet clinics, or small apartment buildings that need laundry capability without eating up too much floor space.

Space efficiency comes with tradeoffs. Stacked setups make repairs harder to access, and finding matching units when one piece fails gets challenging in the used market.

Specialty Equipment (Extractors, Folders, and Stackables)

Used laundromat equipment sometimes includes extractors that remove extra water before drying, folders that automate linen processing, or specialized stackable setups. These serve centralized operations like commercial laundries or large facilities processing serious volume.

Specialty equipment demands careful evaluation since repairs need specific expertise and replacement parts might be scarce for discontinued models.

Top Brands Worth Considering in the Used Market

Brand reputation counts, but age and maintenance history count more. Equipment in laundry operations takes a beating no matter whose name sits on the front.

Speed Queen holds the strongest resale value because they've built durable machines since 1922. Used Speed Queen washers and dryers keep performing when maintained properly, and you can find parts pretty much anywhere. However, older Speed Queen models lack the smart connectivity and efficiency improvements in recent Quantum Series releases.

Maytag Commercial equipment benefits from over a century in commercial laundry. The solid construction and accessible parts network make used Maytag machines serviceable, though buyers should check the specific model's maintenance history instead of just trusting the brand name.

Dexter Laundry delivers reliable performance with lower maintenance needs than some competitors. Used Dexter washers appeal to buyers wanting dependable operation, but older models might lack energy efficiency features that cut operating costs substantially over time.

Continental Girbau and UniMac bring heavy-duty construction built for continuous operation. These brands maintain strong support networks, though their specialized features might need specific expertise for repairs.

Real Clean Group stresses that brand selection is just one piece of the puzzle. A well-maintained mid-tier brand often outperforms a neglected premium machine, and ongoing service support usually determines long-term success more than the initial brand choice.

What to Look for When Evaluating Used Commercial Laundry Equipment

Buying used equipment requires thorough evaluation covering age, condition, capacity match, and real operating costs.

Equipment Age and Usage History

Commercial laundry machines last 10-15 years for frontload models with proper maintenance. A 7-year-old machine for sale might seem like it has half its life left, but usage intensity matters more than calendar age. A hotel washer running 200 loads weekly ages faster than a small gym's machine handling 50 loads.

Unfortunately, usage history is rarely documented well. Sellers might not have maintenance records or hour meters showing actual operation. This uncertainty brings significant risk since machines near end-of-life fail often and unpredictably.

Inspection and Testing Standards

Professional evaluation should check hoses, bearings, door seals, drum condition, and control systems. Test runs verify complete cycles, consistent water temperature, proper extraction, and any unusual vibration or noise.

Many used equipment sales happen "as-is" without inspection chances. Buyers accepting these terms are gambling on unknown wear patterns. Even when inspection happens, visible condition doesn't show worn internal bearings or stressed motor windings that fail weeks after installation.

Capacity Requirements for Your Business

Matching equipment capacity to operational needs optimizes both capital use and workflow. Facilities need approximately 5 square feet of floor space per machine plus extra clearance for operation.

The challenge with used equipment: finding optimal capacity and configuration from whatever's available. Buyers often settle for less-than-ideal specifications to secure available machines, creating operational inefficiencies that stick around for years.

Energy Efficiency Ratings and Operating Costs

This factor carries huge long-term financial impact but gets overlooked during used equipment purchases. ENERGY STAR certified washers use 45% less water than standard models, creating substantial cost differences. With 59% market share in 2023, modern efficient equipment has become the industry norm.

A used commercial washer and dryer saving $5,000 upfront might cost an extra $800-$1,500 yearly in utilities. Over 5 years, those efficiency losses total $4,000-$7,500, wiping out most initial savings while burdening operations with higher ongoing expenses.

The Reality of Quality Assurance for Used Equipment

Professional refurbishment sounds reassuring, but the process lacks any real standards. No universal certification defines what "refurbished" or "professionally tested" actually means for commercial laundry equipment.

Some dealers run rigorous protocols including parts replacement, diagnostic testing, performance verification, and cosmetic restoration. Others do basic cleaning and functionality checks. Without industry-standard testing requirements or third-party certifications, buyers depend heavily on seller reputation and transparency.

Daily preventive maintenance for commercial equipment typically includes cleaning lint filters and drums, checking door seals for leaks, verifying safety features, and testing payment systems where applicable. Predictive diagnostics use IoT sensors monitoring vibration, temperature, water usage, and cycle performance to catch developing issues before failure.

Used equipment arrives without these monitoring histories. Service documentation rarely transfers completely, leaving new owners operating without baseline performance data.

Understanding Warranty and Support Limitations

Manufacturer warranties typically don't transfer to subsequent owners. Original warranties covering 3-5 years of parts and labor apply exclusively to first purchasers with proof of purchase. Used commercial laundry equipment for sale defaults to parts-only coverage at best, more often providing zero warranty protection.

Common warranty exclusions include normal wear on seals, belts, and drums; damage from improper installation; use of non-genuine parts; accidents; and equipment installed in corrosive environments.

Used equipment buyers face three warranty scenarios:

No coverage: Equipment sold "as-is" with all risk shifted to the purchaser. Any failures or repairs become immediate out-of-pocket expenses with service calls costing $120-$500 and major repairs reaching $1,500 or more.

Dealer-provided limited warranty: Some sellers offer 30-90 day coverage on specific components. These warranties typically exclude labor costs, shipping, and installation issues.

Extended service plan purchase: Third-party service agreements cost $500-$1,200 annually per machine but may include exclusions for pre-existing conditions or equipment exceeding certain age thresholds.

Real Clean Group structures service programs around maximizing uptime through preventive maintenance and rapid response. Even expert service can't overcome fundamental equipment reliability issues when machines approach end-of-life.

Installation, Delivery, and Facility Readiness

Used commercial washer and dryer for sale pricing often excludes delivery, installation, and facility prep costs that substantially impact total project budgets.

Delivery and Installation

Professional installation ensures proper connections, leveling, and testing before operation starts. Costs vary based on distance, equipment size, and site accessibility but typically run $200-$800 per machine. DIY installation risks voiding any existing warranty protection and may create unsafe operating conditions or code violations.

Facility Infrastructure Requirements

Commercial laundry rooms need approximately 5 square feet of floor space per machine with additional clearance for operation. More importantly, facilities require infrastructure supporting simultaneous high-volume operation.

Plumbing systems must handle high-volume water flow from multiple machines. Older buildings often lack sufficient drainage capacity, requiring expensive plumbing upgrades. Electrical infrastructure must support simultaneous power demands of multiple high-capacity machines. Inadequate electrical service means panel upgrades or dedicated circuits adding thousands to project costs.

Ventilation requirements address significant moisture and heat generation from commercial equipment. Proper ventilation prevents mold growth, reduces HVAC strain, and maintains acceptable working conditions. Accessibility compliance follows Americans With Disabilities Act requirements: facilities with more than three washing machines must make at least two accessible with appropriate height standards and clear pathways.

These facility preparation costs easily reach $5,000-$15,000 for substantial upgrades. Real Clean Group's renovation services ensure facilities support optimal equipment operation.

Comparing Total Cost of Ownership: Used vs. New Equipment

Purchase price represents only one piece of total cost of ownership. Smart operators calculate complete lifetime expenses including acquisition, installation, utilities, maintenance, downtime, and eventual replacement.

Acquisition and Installation

Used equipment: $3,000-$6,000 per washer, $2,000-$4,000 per dryer

New equipment: $8,000-$15,000 per washer, $5,000-$10,000 per dryer

Installation (both): $200-$800 per machine

Real-World Efficiency Gains from Modern Equipment

The performance gap between used and new equipment shows up in documented savings. Huebsch commercial washers save operators $1,736 annually through reduced utility consumption, while Speed Queen models deliver $1,008 per year in utility savings. For on-premise laundry operations like hotels, UniMac equipment reduces energy consumption by 30%, saving $3,896 annually.

A small facility operating 10 machines sees dramatically different operating costs. Modern equipment's efficiency advantages multiply across multiple units, creating thousands in annual savings that quickly offset higher purchase prices.

Maintenance and Repairs

Annual operating costs for new commercial washers average $1,900-$3,600 (including utilities, repairs, and maintenance), while dryers run $2,000-$3,700. Professional service typically costs $600-$1,200 per washer annually. Used equipment faces higher repair frequency with annual totals reaching $2,300-$7,000 per machine as components wear and fail.

The 34% of laundry operators identifying maintenance costs as a top challenge reflects how aging equipment strains operational budgets. Service calls at $120-$500 each pile up quickly when machines need frequent attention.

Downtime and Lost Revenue

Equipment failures stop operations completely, forcing expensive outsourcing or customer loss when service becomes unreliable. Laundromats generating $40-$60 per machine daily lose $200-$300 for each five-day outage. Frequent failures undermine customer confidence and competitive position.

Technology and Revenue Optimization

Modern equipment includes cloud-based management systems enabling remote monitoring, predictive maintenance alerts, cycle customization, and performance tracking via mobile apps. These features cut labor and service calls by 20-40% while supporting data-driven operational decisions.

Used equipment lacks these capabilities entirely. Operators manage through manual inspection, reactive repairs, and limited operational visibility.

Calculating Your Break-Even Point

Break-even analysis determines how long equipment must operate before cumulative savings offset higher initial investment. This calculation requires honest assessment of all cost factors, not just purchase price.

Example Scenario: 10-Machine Laundromat

Option A: Used Equipment

Initial investment: $50,000 (equipment + installation)

Annual operating costs: $30,000 (utilities + maintenance)

Expected lifespan: 3-5 years before replacement needed

Option B: New Equipment

Initial investment: $110,000 (equipment + installation)

Annual operating costs: $20,000 (utilities + maintenance)

Expected lifespan: 10-15 years

Break-Even Calculation:

Price difference: $60,000 (new costs $60,000 more upfront)

Annual operating cost advantage (new): $10,000

Break-even timeline: 6 years ($60,000 ÷ $10,000 annual savings)

This analysis shows new equipment pays for its higher initial cost within 6 years through lower operating expenses. Given new equipment's 10-15 year lifespan versus 3-5 years remaining for used machines, total cost of ownership strongly favors new equipment despite higher upfront investment.

Key Considerations Missing from Simple Calculations

Equipment reaching end-of-life during the analysis period requires replacement, resetting the comparison entirely. A used machine needing replacement in year 4 creates another $50,000+ capital requirement, while new equipment continues operating reliably.

Technology integration benefits from modern equipment increase revenue by 18-30% through payment system improvements, operational monitoring, and customer experience enhancements. These revenue gains dramatically improve break-even timelines but prove difficult to quantify before implementation.

Financial advisors often suggest hybrid acquisition strategies: purchasing core washers and dryers while leasing ancillary equipment to optimize capital allocation. This approach requires customization based on business model, facility constraints, and growth plans.

Finding the Right Equipment Partner for Your Business

The used commercial laundry equipment market offers legitimate opportunities alongside significant risks. Success depends on rigorous evaluation, honest cost analysis, and realistic expectations about operational realities.

Real Clean Group approaches equipment decisions from a partnership perspective rather than transactional sales focus. With over 50 years of combined experience supporting salons, hotels, healthcare facilities, and multi-family properties across Colorado and Wyoming, they've seen how equipment decisions impact operations for years after installation.

When Used Equipment Makes Sense

Low-volume operations with limited budgets, immediate equipment needs, and realistic expectations about maintenance requirements might find value in carefully selected used equipment from reputable brands with verified service history. The key: honest assessment of total costs and willingness to accept higher operating expenses and maintenance demands.

When New Equipment Provides Superior Value

High-traffic operations prioritizing minimal downtime, facilities targeting energy cost optimization, businesses adopting smart technology for remote management, and space-limited operations benefit from new equipment's efficiency, reliability, and performance monitoring capabilities. Scenarios where modern equipment delivers faster ROI through reduced operating costs and increased uptime expand as utility rates rise and customer expectations evolve.

The Importance of Comprehensive Support

Regardless of equipment choice, success requires dependable service support, rapid parts availability, and facility optimization. Real Clean Group's service model focuses on maximizing uptime through preventive maintenance, expert technicians, and 99% uptime guarantees. Their comprehensive service programs maintain equipment performance long-term while their renovation capabilities ensure facilities support optimal equipment operation.

Conclusion

Used commercial laundry equipment attracts attention through immediate cost savings, but smart operators evaluate total ownership costs, maintenance realities, facility requirements, and long-term operational reliability before committing. The advertised savings often shrink or disappear entirely when accounting for higher utilities, frequent repairs, limited warranties, facility upgrades, and shortened equipment lifespan.

The right equipment decision balances upfront investment against long-term performance, serviceability, and facility readiness. Modern equipment's energy efficiency, smart connectivity, and predictive maintenance capabilities increasingly shift break-even analyses toward new equipment despite higher initial costs. For operations prioritizing reliability, efficiency, and sustainable growth, new equipment often delivers superior total value.

Real Clean Group serves as the trusted advisor helping Colorado and Wyoming businesses navigate these complex decisions. Rather than pushing equipment sales, they partner with operators to assess facility readiness, evaluate equipment options, provide expert maintenance support, source reliable parts, and complete facility renovations when infrastructure upgrades enable better performance.

Whether you're launching a new laundromat, upgrading multi-family property amenities, or modernizing salon or hotel operations, Real Clean Group brings the expertise and support infrastructure ensuring your commercial laundry systems deliver reliable, efficient performance for years ahead.

Ready to make an informed equipment decision backed by expert guidance? Contact Real Clean Group to discuss your specific needs and discover how comprehensive equipment evaluation, facility assessment, and ongoing support create sustainable operational success.