Commercial Washer Repair vs Replace - The Definitive Guide

Table of Contents

When your commercial washer breaks down, the commercial washer repair vs replace decision can dramatically affect your bottom line. Running a busy Colorado salon, hotel laundry room, or healthcare facility means understanding way more than just what's on the repair invoice. Real Clean Group helps businesses throughout Colorado work through these crucial equipment decisions with expert guidance that actually fits your operation.

The stakes here are high. Make the wrong call and you're stuck with escalating repair costs, mounting downtime, and frustrated customers. Get it right and you optimize your investment, boost efficiency, and keep everything running smoothly for years to come.

TL;DR: Repair or Replace a Commercial Washer?

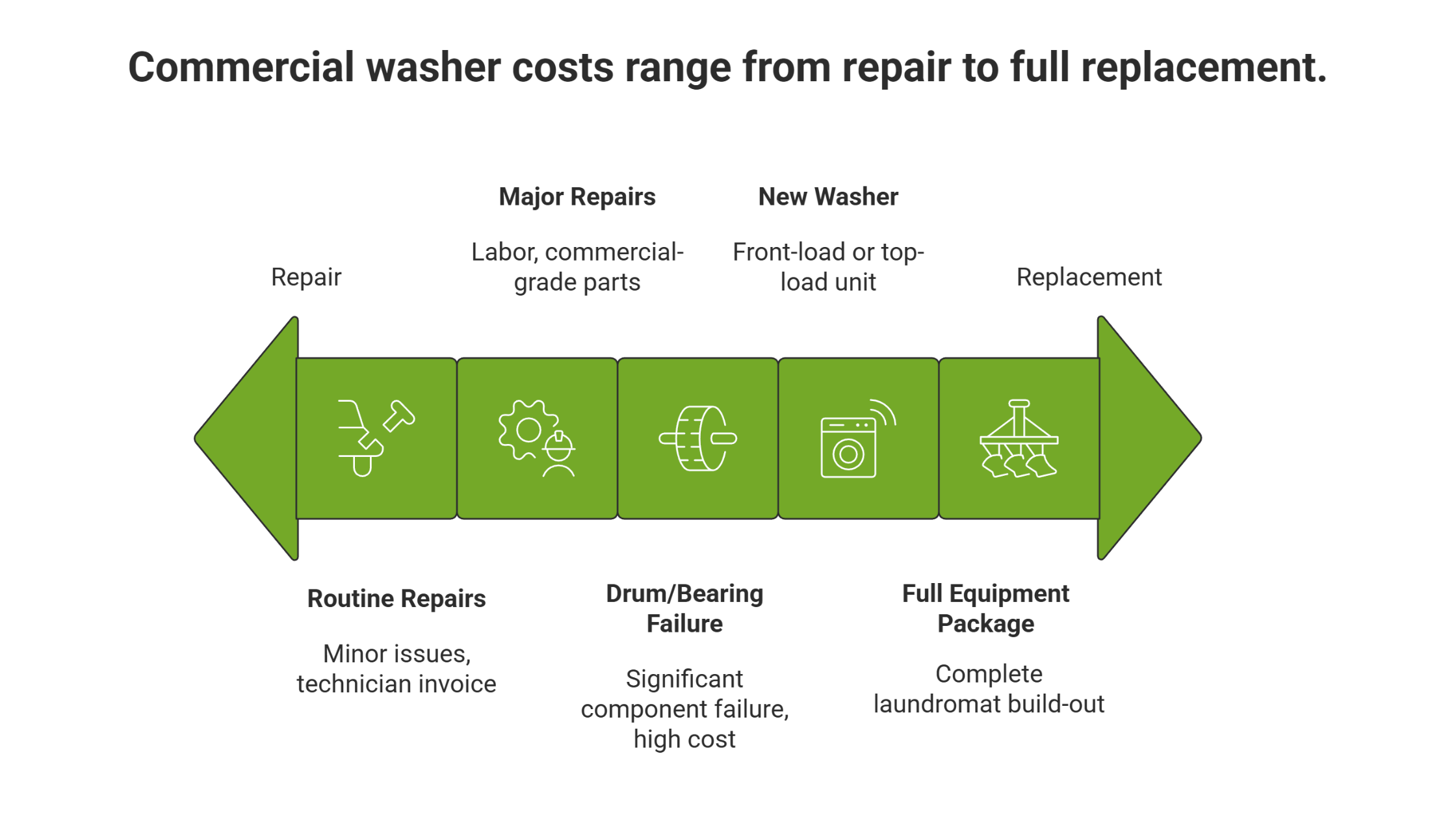

Choosing between repairing or replacing a commercial washer comes down to equipment age, repair frequency, and true total cost of ownership. Repairs make sense for younger machines with isolated issues. Replacement becomes the better investment when failures are frequent, repair costs exceed 40–50% of machine value, or efficiency losses start inflating water, energy, and labor costs. This guide outlines the exact benchmarks to use so you can make a confident, financially sound decision.

Key Points:

Apply the 50% rule: Replace when single repair costs exceed 50% of replacement value

Commercial washers typically last 10-15 years under normal conditions

Repair costs for common issues range from $250-$550 for pumps to $700-$1,500 for drums and bearings

Modern equipment cuts water use by 40-60% and energy consumption by 20-30%

Downtime costs often exceed the repair invoice, making reliability critical

Equipment under 7 years with minor issues usually justifies repair

Frequent breakdowns or obsolete parts signal replacement time

“If a machine can’t stay online, it can’t stay profitable. Reliability is the heart of every successful laundry operation.”

Understanding the Commercial Washer Repair vs Replace Decision

Why This Decision Matters for Your Business

The washing machine repair or replace choice directly affects your operational efficiency, utility costs, and revenue. Equipment downtime doesn't just mean a broken machine. It means lost productivity, overtime labor, rushed service calls, and potentially outsourcing work at premium rates.

For a Colorado hotel processing hundreds of pounds of linens daily, even one day of downtime can cascade into guest complaints and scrambled operations. Healthcare facilities face regulatory pressures and infection control standards that aging equipment struggles to meet. Salons risk turning away clients when towel supply runs short.

Making the wrong call locks you into a pattern of escalating problems. Keep repairing aging equipment and you've created a money pit. Replace too soon and you waste useful equipment life plus capital. The key is understanding which factors truly matter.

How Commercial Washers Differ from Residential Units

Commercial washing machines face dramatically different demands than residential models. They're built for continuous operation, higher volumes, and more intensive loading cycles. A typical commercial washer in a laundromat might run 8-12 loads per day, while healthcare facilities push equipment nearly around the clock.

This constant use means wear patterns develop faster and failures carry higher stakes. Commercial units feature heavier-duty components, larger capacities, and specialized controls for chemical injection and programmable cycles. They're designed to process tough soil levels and handle frequent starts and stops.

The repair and replacement decision framework for commercial equipment must account for these differences. Downtime translates directly to lost revenue or service disruptions. Energy and water costs multiply across hundreds or thousands of daily cycles. The decision isn't just about fixing a machine. It's about protecting your business operations.

Industry Standards for Equipment Lifecycle and Replacement Decisions

DOE Efficiency Standards as Lifecycle Benchmarks

The U.S. Department of Energy maintains energy conservation standards and mandatory test procedures for commercial clothes washers under 10 CFR Parts 431 and 429.

While DOE doesn't set replacement ages, these standards effectively define when older machines become economically obsolete. When DOE updates standards, new models are optimized for current requirements, making previous-generation machines visibly less competitive on energy and water consumption per cycle.

Many large operators align replacement programs with major DOE standard cycles, which occur approximately every seven years by statute for review. Older machines that can't meet contemporary DOE performance thresholds or cost more to run than new ENERGY STAR units are commonly flagged for replacement rather than major rebuilds, even if mechanically repairable.

TRSA Best Practices for Operations Management

TRSA's "Laundry Operations and Management – Digital" (~200 pages, revised to include international standards) serves as the industry operations textbook for plant management. This comprehensive guide covers production and maintenance practices, equipment performance expectations, and financial impacts of equipment on processing.

TRSA frames lifecycle around throughput capacity versus current volume, cost per pound processed (including utilities and labor), and reliability metrics. Rather than strict "replace after X years" rules, their education and resources emphasize economic and reliability-based criteria.

In practice, TRSA members benchmark repair versus replace decisions to whether an asset can support required uptime and maintain wash quality while meeting energy and water performance targets. The focus shifts from calendar age to operational performance and total cost of ownership.

Modern Reliability Benchmarks (2024-2025)

Current industry guides establish operational targets for equipment reliability that drive lifecycle and replacement planning:

Uptime target: 95-98% machine availability

Mean Time Between Failures (MTBF): 2,500-4,000 hours

Average repair time (MTTR): 2-4 hours per incident

Parts availability: same-day for ~90% of components

These benchmarks function as de facto industry standards in technical proposals, lender underwritings, and manufacturer lifecycle ROI tools. Repair is favored when machines maintain ≥95% uptime at acceptable cost and failures remain within the MTBF band. Replacement is favored when chronic failures drop machines below 95% uptime, MTBF trends downward, or parts lead times rise.

Economic Obsolescence Triggers

Manufacturers and distributors publish influential guidelines that many operators treat as policy. Recent trends show operators upgrading to high-extraction machines (350-400 G-force) because they reduce dry time and utility costs, effectively shortening the economic lifecycle of older, lower-performance units.

Modern designs advertise reducing energy use by approximately 30% and significantly cutting water consumption. When these savings are modeled, payback windows of 3-7 years are common. Beyond that, keeping an older, less efficient machine becomes tough to justify economically.

Common manufacturer-advised replacement triggers include major component failures after mid-life when repair approaches 40-60% of replacement cost, inability to meet current utility rebate or ENERGY STAR-level performance, and controls that can't integrate into required IoT and predictive maintenance platforms introduced widely in 2023-2025.

How Long Do Commercial Washers Last?

Average Lifespan by Equipment Type

Commercial washers typically last 10-15 years under heavy commercial use, though actual lifespan varies significantly by machine type and usage intensity. Front-load commercial washers generally achieve 12-15 years of service, while top-load models typically reach 8-10 years before requiring replacement.

Premium washer-extractors designed for on-premise laundries can reach 15-20 years with proper maintenance. These heavy-duty units feature industrial-grade bearings, robust suspension systems, and reinforced frames that withstand continuous operation. Many manufacturers cite design lives up to 20-25 years or 10,000-30,000 cycles in testing, translating to 15-20+ years in typical settings.

Commercial dryers often outlast washers, running 12-18 years due to simpler mechanical systems and lower stress levels. The difference matters when planning equipment lifecycles. A coordinated replacement strategy prevents the inefficiency of mixing very old washers with newer dryers, which can create throughput bottlenecks.

Factors That Impact Equipment Longevity

Maintenance quality stands as the single biggest determinant of commercial washer lifespan. Regular preventive maintenance brings equipment from 10-12 years toward 15-20+ years. We're talking about inspecting belts and bearings, cleaning filters and drains, calibrating controls, and scheduling professional service. Neglect these routine tasks and you'll accelerate wear while triggering cascade failures.

Usage intensity directly correlates with lifespan. High daily cycle counts, near-continuous operation, and chronic overloading accelerate mechanical wear, shorten bearing life, and reduce typical life expectancy. A hotel laundry running three shifts daily puts far more stress on equipment than a salon running a few loads per day.

Water quality and environmental conditions matter significantly. Hard water causes scale buildup on heating elements, valves, and internal surfaces. Corrosive chemicals attack seals and metal components. Poor ventilation increases humidity and accelerates corrosion. Installing water treatment systems and maintaining proper room conditions protects your investment.

Build quality creates baseline differences between equipment tiers. Heavy-duty frames, industrial bearings, quality valves and motors, and rigorous assembly standards explain why some commercial machines reliably exceed 20 years while budget units fail closer to 10 years. The upfront price difference often pays back through extended service life and lower repair frequency.

The 50% Rule: A Quick Decision Framework

How to Calculate Your Repair Threshold

The 50% rule provides a practical starting point for replacement decisions: replace when repair costs reach approximately 50% of replacement value, especially for mid- to late-life equipment. This threshold helps business owners quickly evaluate whether sinking more money into repairs makes financial sense.

Calculate your repair threshold by determining the all-in replacement cost first. Include the purchase price of an equivalent commercial washer plus delivery, installation, required utility modifications, and commissioning. For a typical commercial front-load washer costing $3,000 plus $500 in installation, your 50% threshold would be $1,750.

Compare that threshold to your total economic repair cost. Include technician labor, parts, freight for components, and any near-term follow-on repairs likely within 12-18 months. If bearings need replacement now and seals show wear, treat them as a package rather than separate decisions.

The rule works best for equipment past the early-life stage and beyond major warranty coverage. For newer machines still protected by service contracts, repair even high-cost items (warranties are designed to absorb early-life failures). Apply the 50% threshold mainly to mid- and late-life units when reliability begins declining naturally.

When This Rule Doesn't Apply

The 50% rule breaks down in several common scenarios. For critical-uptime operations tied to strict service-level agreements, even repairs well under 50% may be rejected if failure risk remains high or parts lead times are long. Healthcare facilities and hotels often can't afford the gamble of another breakdown, regardless of repair cost percentages.

Obsolete or unsupported equipment deserves immediate replacement, not repair. When major parts are discontinued, controls use legacy components, or the unit can't meet current codes and efficiency standards, even a 20-30% repair represents poor investment. Future failures and compliance risks are virtually guaranteed.

Adjust the threshold downward when downtime costs are substantial. Facilities running multiple shifts that can't tolerate extended outages often adopt internal thresholds closer to 30-40% of replacement cost. When outages force costly outsourcing or lost contracts, lifecycle experts favor planned replacement over another major repair.

End-of-life structural failures override the percentage rule entirely. Drum damage, bearing-housing cracks, frame corrosion, or multiple major failures within a short window indicate systemic problems. Replacement is recommended once there's evidence of cascading failures, because remaining reliability can't support meaningful payback periods.

Cost Analysis: What to Consider Beyond the Repair Bill

Direct Repair Costs vs. Replacement Investment

Understanding true repair costs requires looking beyond the technician's invoice. Typical commercial washer repairs fall in the $200-$800 range for routine issues, but major failures approach $800-$1,500 when combining hours of labor with commercial-grade parts. Motor and drive system repairs typically cost $400-$900, pump and drainage issues run $250-$550, and control board replacements cost $350-$800.

The most expensive repairs involve drums and bearings. These major component failures commonly cost $700-$1,500 for small- to mid-capacity commercial models, often 30-60% of a new machine's cost. When a repair quote approaches these levels on equipment already past mid-life, replacement economics usually tip in favor of new equipment.

New commercial washers range from $1,500-$5,000 per unit, with front-load models typically costing $2,000-$5,000 and top-load units running $1,000-$3,000. Full laundromat equipment packages often total $180,000-$320,000 for complete build-outs. This context helps frame whether a $1,200 repair on a 12-year-old washer makes sense.

Hidden Costs of Keeping Old Equipment

Aging commercial washers carry substantial hidden costs that repair quotes don't capture. Older machines show 10-25% productivity loss due to frequent stoppages, partial loads, and slower cycles. Each extra 5-10 minutes per load can require 5-15% more labor hours daily, driving up payroll without processing more volume.

Equipment past its prime drives utility costs significantly higher. Older washers may consume 30-40% more water and energy than modern efficient models. At typical commercial volumes, this inefficiency adds $4,000-$7,500 per year per machine in avoidable utility spending. Over a three-year period, that's $12,000-$22,500 in pure waste, often exceeding the cost of replacement.

Emergency service premiums for rush repairs typically run 1.5-2 times standard rates. Overtime labor to catch up after outages adds 5-10% to weekly labor costs during sustained reliability problems. Obsolete parts carry 20-50% higher prices and longer lead times, raising both direct costs and downtime.

Older equipment may require maintaining spare parts inventory "just in case," tying up working capital. Lock-in to long-term service contracts with annual escalators adds percentage points to total operating expenses beyond what a more reliable fleet would require. These indirect costs often dwarf the face value of individual repair bills.

Downtime Impact on Revenue

Commercial laundry downtime carries costs far beyond technician fees. For laundromats, each broken washer removes revenue-generating capacity directly. Coin-operated machines that drive $150-$300 monthly revenue become profit drains during repairs. Multiple units down simultaneously can force customer losses to competitors.

Healthcare and hospitality operations face different but equally serious impacts. Delayed linen turns cause room-out-of-service time, patient-care disruptions, and guest satisfaction penalties. Industry case studies link linen quality issues and delayed processing (often tied to unreliable washers) to 1-3% of revenue at risk in poorly performing laundry operations.

For businesses where clean linens are essential—salons, veterinary clinics, gyms—even short outages force difficult choices. Rush outsourcing at premium rates, turning away appointments, or compromising service quality all carry tangible costs. A Colorado salon might lose $500-$1,500 in service revenue for each day without adequate towel supply.

Lost productivity compounds the problem. Staff standing idle while waiting for repairs, management time coordinating emergency solutions, and customer service resources handling complaints all represent hidden labor costs. When calculating repair versus replace economics, include realistic estimates of these operational disruptions.

Energy Efficiency and Utility Savings

Modern commercial washers cut water use by 40-60% compared to legacy equipment, with ENERGY STAR models using about 45% less water than standard commercial washers from 10-15 years ago. For operations running hundreds of loads monthly, this translates to substantial utility bill reductions and faster ROI on equipment upgrades.

Energy savings prove equally compelling. New high-efficiency commercial washers reduce energy consumption by 20-30% per pound of laundry processed when factoring in reduced hot water volume. High-G-force extraction washers cut dryer energy use by 15-25% by removing more moisture mechanically, creating compounding savings throughout the laundry process.

Documented manufacturer savings demonstrate the impact. Huebsch commercial washers save up to 154,760 gallons of water annually per machine compared to older equipment they replace, with average utility savings around $1,736 per year per machine. Speed Queen's Eco-Cycle technology saves approximately 6,824 gallons monthly and about $1,008 annually per washer-extractor.

For a typical multi-machine operation, these savings add up quickly. Five commercial washers upgraded to high-efficiency models might save $7,500-$8,500 annually in combined utilities. Over a seven-year equipment lifecycle, that's $52,500-$59,500 in savings, often enough to fund the upgrades themselves while delivering superior performance.

Common Commercial Washer Problems and Typical Repair Costs

Motor and Drive System Failures

Motor and drive system issues rank among the most common and costly commercial washer problems. Typical motor repairs cost $400-$900 including parts and commercial-grade labor. These failures manifest as drums not spinning, weak spin cycles, or intermittent operation.

Common root causes include stretched or slipping drive belts, worn pulleys, and overloaded motors running beyond design capacity. Chronic overloading accelerates motor burnout, while inadequate maintenance allows belts to stretch beyond adjustment range. Drive system failures often indicate broader problems with machine loading practices or operator training.

When motors fail on equipment already approaching 10-12 years of age, consider whether the repair investment makes sense against the machine's remaining life expectancy and efficiency. Proactive drive system inspections during quarterly maintenance visits can catch belt wear early, replacing a $30 belt during scheduled service prevents a $700 emergency motor replacement later.

Pump and Drainage Issues

Drainage problems represent one of the most frequent commercial washer complaints, especially in high-lint or mixed-fabric operations. Pump and drainage repairs typically cost $250-$550 including parts and labor for commercial applications.

These issues include clogged drain pump filters and impellers, blocked or kinked drain hoses, and failed drain pump motors. Symptoms include washers not draining, cycle aborts mid-program, or error codes related to water level sensors. Standing water after cycles indicates pump or valve failures requiring immediate attention.

Preventive maintenance dramatically reduces drainage problems. Daily or weekly cleaning of lint filters, pump screens, and drain strainers prevents most blockages before they cause machine failures. Many operations overlook these simple tasks, leading to avoidable service calls and downtime.

When drainage issues become chronic (requiring repairs every few months) the underlying problem often involves water quality, detergent buildup, or inadequate filtration. Address root causes rather than repeatedly treating symptoms to protect your equipment investment.

Control Board and Sensor Problems

Control board failures represent a leading failure class in modern commercial washers alongside mechanical issues. Control board repairs typically cost $350-$800 due to proprietary boards and diagnostic complexity required.

Typical symptoms include machines failing to start, stopping mid-cycle, displaying error codes, or ignoring user inputs. Issues often trace to faulty control boards, software glitches, failed door switches or locks, or misaligned sensors. Intermittent problems prove particularly frustrating and difficult to diagnose.

Modern commercial washers rely heavily on electronic controls for precise water levels, temperatures, cycle timing, and safety interlocks. When these systems fail, machines become inoperable regardless of mechanical condition. Board-level problems increasingly drive replacement decisions when equipment reaches 10+ years and parts become expensive or scarce.

Maintaining an error log by machine (recording codes, frequencies, and clearing methods) helps technicians diagnose patterns. Recurring codes signal underlying issues requiring targeted repairs rather than repeated resets that mask growing problems.

Drum and Bearing Replacements

Drum and bearing work represents the most expensive commercial washer repair category, typically costing $700-$1,500 for small- to mid-capacity models. These failures usually indicate end-of-life conditions for the machine, making replacement more economical than repair.

Bearing failures result from chronic overloading, out-of-balance operation, seal leaks allowing water intrusion, or simply age-related wear after thousands of cycles. Symptoms include loud grinding noises during spin, visible drum wobble, water leaking from the rear of the machine, and excessive vibration even with properly balanced loads.

Commercial operations that routinely overload washers or ignore vibration warnings accelerate bearing wear dramatically. A machine designed for 40-pound loads but regularly stuffed with 60 pounds will fail prematurely, often requiring bearing replacement years before expected lifecycle completion.

When bearing replacement quotes approach 30-50% of a new machine's cost on equipment already past 7-10 years of service, most facility managers choose replacement. The labor intensity of bearing jobs (often requiring 6-10 hours of technician time) drives costs high enough that investing in modern, efficient equipment makes better economic sense.

Water Inlet Valve and Fill System Issues

Leaks and fill faults rank among the most common field service calls for commercial washers. Water inlet valve repairs typically cost $220-$450 including parts and commercial service labor rates.

Problems include unscrewed or damaged inlet hoses, blocked inlet filters, defective inlet valves, worn door seals, and leaking bearings. Symptoms include slow fill times, under-filling that affects wash quality, continuous filling that floods machines, or water pooling around equipment.

Inlet valve issues often stem from poor water quality, inadequate filtration, or simple wear after years of operation. Hard water causes mineral deposits that prevent valves from sealing properly. Debris from building plumbing systems clogs inlet screens and damages valve mechanisms.

Regular inspection and cleaning of inlet filters (a simple 5-minute task) prevents most valve problems. Installing point-of-use water filtration protects valves and extends their service life significantly. For operations in areas with challenging water conditions, these preventive measures pay for themselves many times over.

Red Flags: Warning Signs of Unnecessary Repair Recommendations

Common Tactics That Signal Questionable Advice

Service technicians sometimes recommend unnecessary work or premature replacement. Learning to recognize red flags protects your business from inflated costs and poor decisions. Be cautious when technicians jump straight to "you need a new washer" for a single symptom without showing error codes, opening panels, testing voltage, or identifying a failed part by name and test result.

High-cost part swaps based on "maybe" or "it could be" with no tests or comparisons warrant scrutiny. Reputable techs verify likely failures using basic methods—visual inspection, continuity checks, or pressure/temperature checks. Watch for techs who blame every symptom on "the control board" or "electronics" without examining obvious mechanical or plumbing issues like drainage systems, belts, leaking hoses, or water valves.

Little or no interest in basic maintenance issues you can see represents another warning sign. Common failure causes include clogged filters and drain systems, worn door gaskets and seals, dirty or blocked vents, and mis-calibrated temperature or pressure. When techs skip these fundamentals but immediately recommend costly components or new equipment, question the diagnosis.

Documentation and Process Red Flags

Pressure tactics and one-sided financial comparisons should raise concerns. Phrases like "It's not worth fixing" without written estimates of parts, labor, and expected life after repair, or "Prices are going up today" pushing fast replacement, indicate problematic service providers. Legitimate professionals provide comprehensive documentation and time for informed decisions.

Refusal or reluctance to leave documentation represents a serious red flag. Service providers should provide written work orders describing complaints, tests performed, parts recommended, and explanations. Vague line items like "service kit" or "board package" instead of clear part names and numbers, or hesitation when you ask for photos of failed parts or error code screens, suggest potential issues.

Inconsistent explanations across visits or between machines warrant caution. The same technician giving different causes for identical symptoms in similar machines, or changing explanations when you question costs ("it's the pump… actually it's the motor… might be the board too"), indicates unreliable diagnostics.

How to Verify Repair Recommendations Independently

Always ask for clear, test-based diagnoses before approving major work. Ask: "What specific part has failed? How did you test it? What other probable causes did you rule out and how?" For electronic or board-related calls, request to see error codes and their translation to the diagnosis.

Get at least one independent quote for any job where parts plus labor approach 40-50% of a new machine's cost, or for any recommendation to replace the entire washer or dryer. Use OEM-authorized or factory-trained providers for second opinions when possible, as manufacturers often publish guidance on when to repair versus replace major parts.

Request photos and old parts back. Ask technicians to photograph visible issues (leaks, burnt connectors, broken belts, scorched boards) and bag and tag replaced parts for you. Placing old parts on hold lets another tech or supplier quickly confirm whether they look failed or recently replaced.

Five Things Business Owners Should Verify

First, verify drain and leak basics. Check that lint screens, coin traps, and drain filters are cleared, drain hoses aren't kinked or blocked, and any reported leaks aren't from loose hose clamps, door gaskets, or external plumbing. If these simple items haven't been checked, expensive pump or valve replacements may be premature.

Second, inspect belts, drive components, and vibration sources. For noisy or rough-running machines, verify whether belts and pulleys have actually been inspected for wear and tension. A worn belt is relatively low-cost; recommending a new motor without looking at belts is suspect.

Third, check venting, airflow, and heating on dryers. For "dryer not heating" or "takes too long to dry," independently confirm lint traps and ducts are clean, exterior vent hoods are opening, and no crushed or overly long flex ducts create back-pressure. Clogged vents can mimic heating element or control problems.

Fourth, look up error codes and machine documentation yourself. Many codes point to specific components or simple conditions with recommended troubleshooting steps before major part replacement. If the proposed repair doesn't match what the manual suggests, get another opinion.

Fifth, verify age, remaining life, and total cost comparison independently. Check machine age versus typical commercial life (often 10-15 years), total repair cost compared with a new unit, and your downtime cost. Calculate whether the repair delivers sufficient additional years to justify the expense versus replacing now.

Getting Multiple Quotes: What to Ask

Establishing a process for major repair decisions protects your investment. For any repair exceeding $800 or approaching 40% of replacement value, obtain quotes from at least two qualified service providers. Provide each with identical information about symptoms, machine age, and previous repair history to ensure comparable diagnostics.

Ask each technician the same core questions: What specific component has failed? What tests confirmed this diagnosis? What other potential causes did you rule out? What's the expected equipment life after this repair? Are parts readily available or discontinued? What warranty covers the repair work?

Compare not just the bottom-line costs but the diagnostic process, parts sourcing, and repair approach. A provider offering significantly lower prices but vague diagnostics may be cutting corners. One with higher quotes but comprehensive testing and guaranteed parts availability may deliver better long-term value.

When consulting service providers about repair versus replace, remember they may have incentives to recommend one option. Always verify parts availability independently and consider getting second opinions for repairs exceeding $800. Legitimate providers welcome informed customers and transparent decision processes.

When Repair Makes Financial Sense

Equipment Age Under 7 Years

Commercial washers under 7 years old with no pattern of chronic issues usually justify repair rather than replacement. These machines remain in the first half of their expected 10-15 year service life, with sufficient remaining useful life to recover repair costs through continued operation.

When a 3-5 year old commercial washer needs a $600 motor replacement, the decision becomes straightforward. The machine still has 5-10 years of potential service ahead, and the repair cost represents only 15-20% of replacement value for a typical $3,000-$4,000 commercial front-load washer.

Age alone doesn't determine the right choice, but it provides critical context. Younger equipment benefits from more readily available parts, simpler service histories, and typically better energy efficiency than models from previous generations. These factors shift repair economics favorably compared to older units.

Minor Component Failures

When failures involve discrete, well-bounded components (belts, pumps, valves, door locks, sensors, or isolated control boards) repair typically makes economic sense. These targeted fixes cost $200-$800 and resolve in a single service visit with minimal downtime.

Minor component issues indicate normal wear rather than systemic end-of-life problems. A worn drive belt after 5 years of service is expected maintenance, not a sign the entire machine is failing. Replacing it restores full functionality for a fraction of replacement cost.

The key distinction involves whether the failure suggests broader problems. A leaking pump on an otherwise healthy 6-year-old washer warrants repair. The same pump leak on a 13-year-old machine with previous bearing noise, declining performance, and corroded components may signal deeper issues making replacement more prudent.

Maintenance records help identify patterns. When a specific machine requires multiple minor repairs within 6-12 months, the accumulating downtime and costs often justify replacement even if individual repairs seem reasonable. Track total repair spend per machine annually to catch these patterns.

Active Warranty Coverage

Equipment under manufacturer warranty or comprehensive service contracts strongly favors repair rather than replacement. Warranty terms typically cover parts and sometimes labor for mechanical and electrical failures, minimizing or eliminating out-of-pocket repair costs.

Most new commercial washers include 3-5 years of parts warranty, with longer coverage on major components like frames, tubs, and transmissions. Some manufacturers offer 7-10 year extended warranties on select models. When failures occur during warranty periods, repair represents the economically rational choice.

Full-service lease or rental contracts often include repairs and maintenance as part of monthly fees. In these arrangements, downtime remains the primary concern rather than repair cost. As long as the provider meets uptime targets and repairs restore performance, continuing to repair makes sense under contract terms.

Review warranty documentation carefully to understand what's covered. Many commercial warranties exclude labor after the first year, cover only specific components, or require authorized service centers. Factor actual out-of-pocket costs when evaluating repair decisions on warranted equipment.

Strong Overall Equipment Condition

When a commercial washer's overall condition remains good despite needing a specific repair, investing in the fix makes financial sense. Good condition means consistent performance, minimal previous repair history, no visible corrosion or structural wear, and operating efficiency comparable to fleet averages.

A machine that has required only routine maintenance for 6 years and now needs a $400 pump replacement represents a solid repair candidate. The equipment has demonstrated reliability and shows no signs of accelerating degradation. The repair addresses an isolated issue without opening the door to cascade failures.

Visual inspection reveals condition clues. Check for rust on the frame, worn door seals, damaged controls, excessive noise, or vibration during operation. Machines showing multiple wear indicators often signal approaching end-of-life regardless of chronological age.

Clear Signs It's Time to Replace Your Commercial Washer

Frequent Breakdowns and Rising Repair Frequency

When a commercial washer requires more than 3-4 unplanned repairs annually, replacement typically delivers better value than continued reactive maintenance. Frequent breakdowns indicate systemic degradation rather than isolated component failures, making additional repairs a money pit.

Track service calls per machine to identify chronic problem units. A washer requiring technician visits in January, April, July, and October has crossed the threshold from normal wear to unreliable equipment. Each repair likely addresses symptoms without solving underlying degradation.

Rising repair frequency also multiplies indirect costs. Repeated downtime disrupts operations, forces staff into workarounds, and consumes management time coordinating service. Customer impacts accumulate—hotels scrambling for clean linens, salons turning away appointments, healthcare facilities delaying procedures.

The pattern matters more than individual repair costs. Even if each breakdown costs only $300-$400, four repairs annually total $1,200-$1,600 plus substantial downtime costs. That ongoing expense rivals annual lease payments on new equipment that would deliver dramatically better reliability.

Repair Costs Exceeding 50% of Replacement Value

When a single repair quote exceeds roughly 50% of replacement cost, or cumulative repairs over 12 months reach that threshold, most facility managers choose replacement. This rule of thumb provides a clear financial trigger point for equipment lifecycle decisions.

For a commercial washer with a $3,500 replacement cost, the 50% threshold stands at approximately $1,750. A drum and bearing replacement quoted at $1,400 on a 10-year-old machine approaches this limit. When you factor in likely additional repairs within the next year, replacement economics typically favor new equipment.

The rule assumes mid- to late-life equipment. For newer machines, especially those still under warranty, higher repair percentages may be acceptable because substantial service life remains. Conversely, for very old equipment (12-15+ years), even repairs at 30-40% of replacement value often don't make sense due to limited remaining life and continued reliability risk.

Document your decision criteria clearly. Establishing internal policies (such as "replace when repair costs exceed 40% of replacement value on equipment over 8 years old") brings consistency to equipment decisions and prevents emotional attachment to aging assets.

Obsolete Parts and Limited Service Availability

When essential parts become difficult to source, replacement timelines often shift favorably. Discontinued models, legacy control systems, and proprietary components that manufacturers no longer support create both direct cost pressures and operational risks from extended downtime during parts procurement.

Obsolete parts typically carry 20-50% price premiums due to scarcity and aftermarket sourcing. Lead times stretch from days to weeks, meaning a simple repair might take your washer out of service for extended periods. The combination of high costs and long waits makes continued repair economically questionable.

Beyond immediate repair challenges, obsolete equipment signals growing risk. When the next breakdown occurs (and it will), you may face even worse parts availability or discover the component simply isn't manufactured anymore. This uncertainty makes business planning difficult and increases downtime probability.

Service technician availability matters too. As equipment ages out of common service, fewer technicians maintain expertise on older models. Finding qualified service becomes harder and more expensive. This reduced service ecosystem pushes lifecycle decisions toward modern, well-supported equipment.

Declining Performance and Customer Complaints

Performance degradation that persists despite repairs signals fundamental equipment decline. Longer cycle times, poor soil removal requiring rewashes, inconsistent temperatures, or incomplete spin extraction all indicate machines struggling to meet operational demands.

Customer complaints provide clear feedback about declining performance. Hotel guests complaining about scratchy linens, salon clients noticing dingy towels, or healthcare staff raising concerns about cleanliness standards all point to equipment failing to deliver acceptable results.

Even a 2-5% rewash rate increases water, chemicals, energy, and labor costs per pound processed. When older washers consistently miss cleanliness standards, the cumulative cost of rewashing (plus the quality and reputation risks) often exceeds the investment in efficient replacement equipment.

Excessive Water or Energy Consumption

When a commercial washer's utility consumption runs 25-30% higher than comparable modern equipment, the operating cost differential often justifies replacement on efficiency grounds alone. New ENERGY STAR commercial washers cut water use by approximately 45% compared to standard commercial models.

Track utility consumption per pound of laundry or per cycle to identify inefficient equipment. A washer consuming 30 gallons per load versus 15 gallons for a high-efficiency model wastes 15 gallons per cycle. At 200 loads monthly, that's 3,000 gallons. Multiplied by water and sewer rates, the monthly waste adds up quickly.

Energy inefficiency follows similar math. Older washers using more hot water and longer cycle times drive electricity and gas costs significantly higher. Modern equipment delivering 20-30% energy savings can pay back the upgrade investment through utility reductions within 3-5 years.

Colorado's utility rates and water scarcity make efficiency particularly important for businesses in the region. Payback periods for high-efficiency equipment upgrades often run just 2-3 years while simultaneously reducing environmental impact.

Evaluating New Technology and Efficiency Gains

Water and Energy Savings in Modern Equipment

Modern commercial washers achieve 40-60% water reductions compared to legacy equipment, driven by smart sensors that adjust water levels based on load size and fabric type. Water recycling systems capture and reuse rinse water in subsequent cycles, delivering approximately 60% water savings versus conventional once-through designs.

Energy savings prove equally dramatic. ENERGY STAR commercial washers reduce energy consumption by about 9% on DOE test metrics, but when combined with reduced hot water volume, total system energy savings typically reach 20-30% per pound of laundry processed. Heat recovery systems reclaim exhaust energy, delivering an additional 30% savings.

High-G-force extraction represents another efficiency breakthrough. Modern 400G extractors cut dryer energy use by approximately 30% by removing more moisture mechanically before drying. This reduces both energy consumption and cycle times, improving throughput without increasing utility load.

For a typical 20-machine commercial laundry operation, these efficiency improvements translate to $30,000-$50,000+ in cumulative utility savings over a seven-year equipment lifecycle. The payback period on efficient equipment often runs just 2-3 years through pure operating cost reduction.

Improved Cycle Times and Throughput

Modern commercial washers deliver faster cycle times through optimized controls, better water management, and higher extraction speeds. Smart washer controls reduce cycle times by around 12% while maintaining or improving wash quality, directly increasing daily throughput capacity.

Higher extraction G-forces (350-450G in current models versus 100-200G in older equipment) reduce remaining moisture by 35-40%. This cuts dryer cycle times by 20-35%, creating a compound throughput benefit across the entire laundry process. More loads completed per day without adding equipment or floor space.

Larger capacities in modern machines further boost efficiency. Twenty-pound capacity washers replacing fifteen-pound units reduce the number of loads by 20-30% at the same total volume. Fewer loads mean less start/stop time, lower labor requirements, and reduced wear on equipment.

For Colorado salons or small hotels operating near capacity, throughput improvements can eliminate the need for additional equipment or extended hours. A facility processing 300 pounds daily that gains 15% throughput through upgraded washers effectively adds 45 pounds of capacity (equivalent to an extra small washer) without the floor space or utility requirements.

Enhanced Features That Drive Revenue

IoT connectivity and remote monitoring transform commercial laundry management. Modern washers send real-time status updates, performance data, and maintenance alerts to mobile devices, allowing managers to track equipment from anywhere. This visibility reduces unplanned downtime and optimizes machine utilization across the fleet.

Predictive maintenance features use sensor data to identify developing problems before failures occur. Detecting abnormal vibration patterns, increased power consumption, or longer cycle times allows scheduling repairs during low-demand periods rather than dealing with emergency breakdowns during peak hours.

Advanced control systems offer 99+ programmable cycles for different fabric types, soil levels, and customer requirements. This programmability allows fine-tuning wash processes for optimal results, reducing rewash rates and chemical consumption while improving finished quality.

For multi-location operations, centralized monitoring consolidates fleet management. Managers track performance metrics, utility consumption, and maintenance needs across all sites from a single dashboard. This visibility supports data-driven decisions about equipment upgrades and optimization opportunities.

Alternative Options: Beyond Repair or Purchase

Leasing as a Strategic Solution

Commercial equipment leasing typically runs $150-$400 per machine per month for 3-7 year terms, offering an alternative to large capital outlays. Lease payments are generally 100% tax-deductible operating expenses, improving cash flow compared to capitalized purchases that must be depreciated.

Leasing preserves working capital for other business needs. Rather than tying up $60,000-$200,000 in equipment purchases, businesses maintain flexibility to invest in marketing, facility improvements, or inventory. Monthly lease costs become predictable operating expenses that are easier to budget than unpredictable repair bills.

Most commercial leases include maintenance and repairs, eliminating surprise service costs. When equipment breaks down, the leasing company handles repairs without additional charges. This bundled approach converts variable maintenance costs (which can run $600-$1,200 per washer annually) into fixed monthly payments.

Shorter lease terms (3-5 years) enable regular technology refreshes. Businesses upgrade to new equipment every few years, maintaining modern efficient machines without dealing with aging assets. This approach proves particularly valuable in fast-moving markets where technology improvements deliver meaningful competitive advantages.

Certified Refurbished Equipment

Certified refurbished commercial washers cost 30-60% less than new equipment while delivering performance close to new machines. Reputable dealers thoroughly inspect, repair, and test refurbished units, providing warranties typically ranging from 90 days to 2 years depending on age and condition.

Refurbished equipment suits budget-conscious operations that need immediate capacity without full replacement budgets. A business facing a critical washer failure might find a certified refurbished unit provides reliable service at $1,200-$2,000 versus $3,500-$4,500 for new equipment.

The tradeoff involves shorter warranty periods and potentially older technology. Refurbished machines may lack the latest efficiency features, IoT connectivity, or advanced controls found in current models. Energy and water consumption likely runs higher than new equipment, creating ongoing operating cost differentials.

Evaluate refurbished options carefully. Work with established dealers who stand behind their reconditioning process, offer meaningful warranties, and provide clear documentation of what work was performed. Avoid "as-is" used equipment without professional inspection and warranty coverage.

Hybrid Approaches for Multi-Unit Operations

Large facilities can deploy hybrid strategies combining repair, strategic replacement, and phased upgrades. Replace the highest-volume, most critical machines first with efficient equipment while continuing to repair low-use or backup units that still meet minimum requirements.

Stagger replacements over 2-3 years to spread capital costs while progressively improving fleet efficiency and reliability. Replace 3-5 machines annually rather than trying to fund complete fleet replacement at once. This approach balances financial constraints with operational improvements.

Mix new and refurbished equipment based on application intensity. Install new high-efficiency washers for primary production while using certified refurbished units for overflow capacity or backup roles. This targeted deployment optimizes return on investment.

How to Make Your Decision: A Step-by-Step Process

Step 1: Assess Current Equipment Condition

Start with comprehensive equipment assessment documenting age, model, usage history, and visible condition. Record how many daily cycles each machine runs, maintenance history for the past 2-3 years, and current performance metrics like cycle times and utility consumption.

Inspect machines systematically for warning signs: unusual noises or vibration, visible rust or corrosion, damaged controls or door seals, leaks or standing water, and any recent error codes. Compare performance to manufacturer specifications and your fleet averages to identify underperforming units.

Review maintenance logs to understand repair patterns. A machine requiring service every 2-3 months signals growing unreliability. Calculate total repair spend per machine over the past 12-24 months to understand cumulative investment in aging equipment.

Consider operational impact. Does the equipment meet current volume demands? Are cycle times adequate for your business model? Do customers or staff raise quality concerns? These qualitative factors matter as much as mechanical condition.

Step 2: Get Accurate Repair Estimates

Obtain detailed repair quotes from qualified commercial laundry technicians. Ensure estimates include all necessary parts, labor at realistic hourly rates, diagnostics fees, and any follow-on work likely needed within 6-12 months.

For major repairs, consider getting second opinions. A $1,200 repair quote might get confirmed, or you might learn the actual problem is different and costs more or less than the initial diagnosis suggested. Independent assessment protects against over-repair or misdiagnosis.

Ask technicians about parts availability and lead times. A $600 repair that takes three weeks for parts procurement has very different business impact than the same repair completed in two days. Factor downtime duration into your cost analysis.

Question whether the repair addresses root causes or just treats symptoms. Replacing a pump without fixing the drainage restriction that killed it wastes money on a repair that will fail again shortly. Understand what caused the failure and whether the proposed fix prevents recurrence.

Step 3: Calculate Total Cost of Ownership

Project total ownership costs for both repair and replacement scenarios over a realistic time horizon (typically 3-5 years). For the repair option, include the immediate repair cost plus estimated additional repairs based on equipment age, ongoing maintenance, higher utility costs, and downtime impacts.

For replacement, calculate all-in acquisition costs including equipment purchase, delivery, installation, utility modifications, staff training, and financing if applicable. Factor in expected utility savings from efficient equipment, reduced maintenance costs, and decreased downtime over the comparison period.

Use realistic assumptions about equipment lifespan and repair frequency. An 11-year-old commercial washer getting a $900 repair might require another $1,500 in work over the next three years based on its age and condition. Compare that $2,400 total to new equipment costs minus utility savings and reliability gains.

Include downtime costs in your model. If equipment failures cause $500-$1,000 in lost productivity or revenue per incident, and older equipment breaks down 3-4 times annually while new equipment might break down once, the reliability difference represents $1,500-$3,000 in annual value beyond repair costs.

Step 4: Evaluate Business Impact

Consider how equipment decisions align with broader business goals and operational requirements. Growing businesses need reliable capacity that scales with demand. Stable operations prioritize cost optimization and risk management. Declining segments might extend equipment life while minimizing investment.

Assess competitive positioning. If competitors offer faster service or higher quality due to better equipment, falling behind creates strategic risk. A Colorado salon competing with faster-turnaround competitors may need upgraded equipment regardless of pure financial analysis.

Factor in compliance and regulatory requirements. Healthcare facilities must meet infection control standards. Government operations face procurement rules and budget cycles. Hotels balance guest expectations against capital constraints. These contextual factors override simplistic cost comparisons.

Think about staff and customer impacts. Unreliable equipment frustrates employees, complicates scheduling, and creates service disruptions customers notice. The cost of reputation damage and staff turnover can exceed the financial difference between repair and replacement.

Step 5: Consider Your Long-Term Plans

Match equipment decisions to your business timeline. If you plan to sell or close within 2-3 years, minimal repairs that maintain basic functionality make sense. Investing in new equipment you won't fully utilize wastes capital.

Growing operations justify investment in scalable, efficient equipment that supports expansion. Upgrading proactively before capacity constraints limit growth proves more cost-effective than emergency purchases during crisis.

Facility renovation plans influence timing. If you're planning significant facility upgrades within 12-18 months, coordinate equipment decisions with that timeline. Replacing equipment now that you'll relocate during renovation wastes the installation investment.

Preventive Maintenance to Extend Equipment Life

Essential Maintenance Tasks and Schedules

Implement structured maintenance programs combining daily staff tasks with professional quarterly or semi-annual service. Daily tasks include inspecting for leaks and unusual noises, cleaning lint filters before each use, checking drain and inlet screens, and verifying door seals function properly.

Weekly maintenance involves thoroughly cleaning lint filters beyond user-level cleaning, inspecting drive belts for wear and proper tension, checking water inlet hoses and screens for damage or debris, cleaning soap dispensers, and ensuring drains remain clear.

Monthly tasks include inspecting belts and bearings systematically, checking heating elements and airflow, lubricating components per manufacturer specifications, inspecting electrical connections for overheating signs, testing safety features, and verifying water temperatures for accuracy.

Schedule professional service quarterly or semi-annually where certified technicians conduct comprehensive inspections, calibrate controls and sensors, assess water pressure and drainage, and proactively replace worn parts before failure. This structured approach extends equipment life from 10-12 years toward 15-20 years while dramatically reducing unplanned downtime.

Early Warning Signs to Monitor

Train staff to recognize and report performance changes that signal developing problems. New or increasing vibration, banging, or unusual motor sounds typically indicate mounting issues, out-of-balance loading, or failing bearings requiring investigation.

Monitor cycle performance for drift. Slower cycles, incomplete rinse or extraction, or inconsistent results suggest timer issues, partially restricted water flow, failing pumps, or control problems. Track standard cycle times weekly and investigate when times increase beyond normal ranges.

Watch for water where it shouldn't be. Recurrent leaks, drips, or slow drainage indicate worn door gaskets, loose connections, or valves beginning to fail. Address seepage immediately rather than waiting for visible leaks—early intervention prevents major damage.

Track rising utility costs per pound of laundry processed. Increasing water, gas, or electric consumption without volume changes signals declining mechanical efficiency, clogged components, or programming drift. Set trigger thresholds that prompt investigation and corrective action.

What to Do Next: Taking Action on Your Decision

Armed with comprehensive understanding of your equipment condition, repair options, replacement costs, and business impact, you're ready to act. For equipment clearly past viable repair (typically 12+ years old with major failures and repair costs exceeding 40-50% of replacement value), move forward confidently with replacement.

For mid-life equipment (6-10 years) with moderate repair needs, run the numbers carefully. Calculate total cost of ownership over 3-5 years for both scenarios including repairs, maintenance, utilities, and downtime. Let the data guide your decision rather than emotional attachment to existing equipment.

When replacement makes sense, choose equipment that fits your actual needs. Avoid over-buying capacity you'll never use or under-buying capacity that creates future bottlenecks. Consider efficiency features, technology capabilities, and total lifecycle costs rather than just purchase price.

Contact Real Clean Group to discuss your specific situation and explore solutions tailored to your Colorado business. Call 303-505-2509 to speak with their equipment specialists, schedule a facility assessment, or request repair quotes. You can also email audrey@realclean.group or visit their Denver office at 2045 S Valentia St, Unit 6 (by appointment).

Frequently Asked Questions

Is it cheaper to repair or replace a commercial washing machine?

The answer depends on equipment age, repair costs, and remaining useful life. Generally, repair is cheaper when the machine is under 7 years old, repair costs stay below 40-50% of replacement value, and the equipment shows good overall condition. Replacement becomes more cost-effective when equipment exceeds 10 years, requires frequent repairs, or faces repair costs approaching half the replacement value.

Factor in hidden costs like downtime, higher utilities from inefficient equipment, and the probability of additional repairs soon. A $1,200 repair on a 12-year-old washer might seem cheaper than a $3,500 replacement, but when you add likely repairs over the next 2-3 years plus higher utility costs, replacement often delivers better total value.

How much does commercial washer repair typically cost?

Typical commercial washer repairs range from $200-$800 for common issues. Motor and drive system repairs cost $400-$900, pump and drainage problems run $250-$550, and control board replacements typically cost $350-$800. The most expensive repairs involve drums and bearings, commonly costing $700-$1,500.

Actual costs vary based on the specific problem, machine model, parts availability, and local service rates. Major metropolitan areas often see higher labor rates than rural locations. Complex diagnostics, proprietary parts, or equipment requiring extensive disassembly push costs toward the higher end of these ranges.

When should I replace my commercial washing machine?

Replace commercial washers when they reach 10-15 years of age, especially if accompanied by frequent breakdowns, rising repair costs, or declining performance. Other replacement triggers include repair quotes exceeding 50% of replacement value, obsolete parts with limited availability, excessive water or energy consumption, and performance issues affecting customer satisfaction.

Consider replacement proactively when efficiency improvements from modern equipment deliver meaningful utility savings (often 30-60% reductions in water and energy use). For high-volume operations, the cumulative savings can fund upgrades within 2-4 years while delivering superior reliability and capacity.

How often should commercial washers be replaced?

Commercial washers should typically be replaced every 10-15 years depending on usage intensity and maintenance quality. Front-load models generally last 12-15 years in moderate-use settings, while top-load commercial washers typically reach 8-10 years. Heavy-use operations like 24/7 laundromats may see shorter lifecycles of 7-10 years.

Replacement timing depends more on condition and economics than strict age limits. Well-maintained equipment in light-duty applications might justify operation beyond 15 years, while poorly maintained machines in harsh environments may require replacement at 7-8 years. Track repair frequency, costs, and performance to identify optimal replacement timing.

Can I repair a commercial washer myself?

DIY repair of commercial washing machines is strongly discouraged due to safety hazards, warranty implications, and technical complexity. Commercial washers combine high-voltage electrical systems, pressurized water, and heavy mechanical components that create serious risks of electrical shock, injury, flooding, and fire when handled incorrectly.

Limit in-house work to user-level maintenance tasks specifically recommended in owner's manuals: cleaning filters, checking hoses, inspecting seals, and basic visual inspections. For any internal, electrical, mechanical, or control system work, use qualified commercial laundry technicians to protect safety, preserve warranties, and ensure proper repairs.

What's the warranty coverage on commercial washer repairs?

Standard new commercial washer warranties typically provide 3-5 years on parts, with some manufacturers offering 7-10 year coverage on select models. Labor coverage often runs just 1 year or may be excluded entirely, making parts-only warranties common after the first year.

Extended warranties and service contracts from dealers or third parties add longer labor coverage and protection beyond manufacturer terms. These plans typically cost additional money but can prove valuable for high-use equipment. Warranty coverage generally excludes wear items like belts and seals, damage from misuse, and repairs by unauthorized technicians. Always review warranty terms carefully and maintain documentation of required maintenance to protect coverage.

Conclusion

The commercial washer repair vs replace decision ultimately comes down to equipment age, repair costs, reliability, and total lifecycle economics. While the 50% rule provides a useful framework (replace when repair costs exceed half the replacement value), real-world decisions require evaluating downtime impacts, efficiency gains, and your specific operational needs.

Equipment under 7 years with minor issues usually justifies repair. Machines over 10 years facing major component failures typically warrant replacement, especially when factoring in efficiency improvements and avoided future repairs. Between those boundaries, careful cost analysis and business impact assessment guide the right choice.

Ready to make your decision? Consult qualified technicians, get multiple quotes for major repairs, and verify recommendations independently. Explore your full range of options (repair, replacement, leasing, or refurbished equipment) to find the solution that maximizes uptime, minimizes costs, and supports your long-term success.