How Commercial Laundry Machine Repair Protects Your Profit

Table of Contents

When your commercial laundry machines repair needs arise unexpectedly, every minute of downtime costs you revenue and disrupts operations. A malfunctioning washer in a busy hotel laundry room or a failing dryer at a Colorado salon can quickly cascade into dissatisfied customers and mounting losses. Real Clean Group delivers expert repair services designed specifically for businesses across Colorado and Wyoming, combining rapid response times with deep technical expertise to keep your laundry operations running smoothly.

Commercial laundry equipment operates under demanding conditions, handling hundreds of cycles monthly while supporting your business's daily operations. Whether you manage a multi-housing facility, operate a healthcare laundry, or run a bustling laundromat, reliable equipment isn't optional. It's essential to your bottom line.

TL;DR: Keep Your Commercial Laundry Running, Not Bleeding Cash

Commercial laundry equipment failures create immediate operational and financial pressures. Real Clean Group provides comprehensive repair services for washers, dryers, and specialized equipment across Colorado and Wyoming, serving hotels, salons, healthcare facilities, multi-housing properties, and laundromats. Our EPA-certified and manufacturer-trained technicians diagnose and repair control systems, mechanical components, and electrical issues efficiently.

Key Points:

Repair costs: Service calls range $120–$500 for typical repairs; major components cost $350–$1,500

Downtime impact: Hotels and healthcare facilities lose $100-$400 per hour during equipment outages

Equipment lifespan: Commercial machines typically deliver 10-15 years of service with proper maintenance

Repair vs replacement: Replace when annual repair costs exceed 20% of replacement value

Prevention ROI: Energy-efficient equipment saves $1,008–$3,896 annually per machine in utility costs

Real Clean Group combines manufacturer-specific expertise with local Colorado presence, offering both emergency and scheduled maintenance to keep your facility operating at peak efficiency.

“Downtime is a direct top to your revenue. Reliable commercial laundry machine repair keeps operations flowing, protects your investment, and saves you from costly surprises.”

Signs Your Commercial Laundry Equipment Needs Immediate Repair

Recognizing early warning signs saves you from costly breakdowns and revenue loss. Your equipment communicates problems through specific symptoms that demand immediate attention.

Performance and Operational Warning Signs

Water pooling beneath your washers signals failing seals or damaged hoses. These issues escalate quickly from minor inconvenience to flooding damage. Excessive vibration during spin cycles indicates worn bearings, unbalanced drums, or loose mounting hardware that will worsen with continued operation.

Error codes flashing on display panels aren't random. They're your machine's diagnostic system alerting you to sensor failures, electrical malfunctions, or mechanical issues. Modern machines from Speed Queen and Maytag feature built-in diagnostic systems designed to catch problems before complete failure.

Clothes emerging wet from wash cycles or damp from dryers point to drainage failures, heating element problems, or blocked vents. These issues directly impact your throughput and customer satisfaction while driving up utility costs. Longer cycle times signal declining efficiency from clogged filters, failing heating elements, or worn mechanical components.

Safety Concerns Requiring Urgent Attention

Burning smells from any laundry equipment demand immediate shutdown and professional inspection. These odors indicate overheating motors, worn belts, or electrical faults (all fire hazards requiring urgent commercial laundry machine repairs).

Electrical issues manifest as tripped breakers, flickering displays, or machines that won't start consistently. These problems reflect serious wiring faults, failing control boards, or grounding issues that pose electrocution risks.

Door lock malfunctions create safety hazards when machines operate with unsecured doors or trap users mid-cycle. Persistent water leaks increase slip-and-fall risks while damaging surrounding flooring and equipment. According to OSHA guidelines for laundry facilities, insufficient equipment maintenance directly increases workplace incidents, making prompt repairs both a financial and safety imperative.

Commercial Laundry Equipment We Repair

Real Clean Group's technicians service the full spectrum of commercial laundry systems operating across Colorado's diverse business landscape.

Commercial Washers and Washing Systems

Front-load commercial washers dominate modern laundromats and multi-housing facilities for their water efficiency and cleaning performance. Our team repairs these workhorses when drum bearings fail, door seals leak, or control systems malfunction. Top-load commercial washers require different diagnostic approaches when transmission issues or agitator problems arise.

High-capacity washer-extractors serve on-premise hotel laundries and industrial laundry facilities, featuring advanced extraction speeds that reduce drying times. These hardmount and softmount systems demand specialized expertise when suspension systems wear or high-G extraction features malfunction.

Stack washer units maximize space efficiency in salons, veterinary clinics, and apartment buildings. When these vertical systems develop drainage issues, heating problems, or control board failures, our repair process addresses both washer and dryer components efficiently.

Commercial Dryers and Drying Equipment

Gas and electric commercial dryers each present unique repair challenges. Gas dryer repairs involve ignitor replacement, burner assembly cleaning, and gas valve servicing (work requiring specialized certification and safety protocols). Electric dryers need heating element replacement, thermostat calibration, and electrical connection servicing.

Stack dryers serving space-constrained facilities face particular repair complexity when drum motors fail or moisture sensors malfunction. High-capacity single-pocket dryers anchor commercial laundry operations in hotels, gyms, and healthcare facilities. When lint buildup causes overheating, motors burn out, or control systems fail, our technicians restore these critical assets quickly.

Specialized Laundry Equipment

Barrier washer-extractors maintain hygiene protocols in healthcare facilities by preventing cross-contamination between soiled and clean textiles. These specialized machines require expert servicing of their dual-door systems, interlocks, and contamination barriers.

Finishing equipment including ironers and folding machines completes the laundry process for hotels and uniform services. Payment system repairs restore revenue collection when coin mechanisms jam, card readers fail, or contactless systems stop responding. Modern IoT-enabled monitoring systems require software updates, connectivity troubleshooting, and sensor recalibration.

Brands and Models Our Technicians Service

Real Clean Group's manufacturer-trained technicians service equipment from industry-leading manufacturers, bringing brand-specific expertise to every repair call. As an exclusive licensed distributor of Huebsch Laundry Machines for Colorado and Wyoming, we maintain deep technical knowledge of Huebsch systems, including the advanced Galaxy 600 Series with its cloud connectivity and diagnostic capabilities.

Speed Queen represents the gold standard for commercial laundry durability. Our Speed Queen service expertise encompasses the Quantum Touch Range's advanced controls, commercial washer transmissions, and heavy-duty dryer components.

Maytag commercial equipment serves countless laundromats and multi-housing properties. Our Maytag commercial washer repair services address the Maxima Series' automatic chemical injection systems, robust motors, and advanced diagnostic features.

Our service portfolio extends to Electrolux Professional's Line 6000 with intelligent management systems, Dexter's programmable heavy-duty machines, B&C Technologies' customizable solutions, and Whirlpool's space-saving stack pairs.

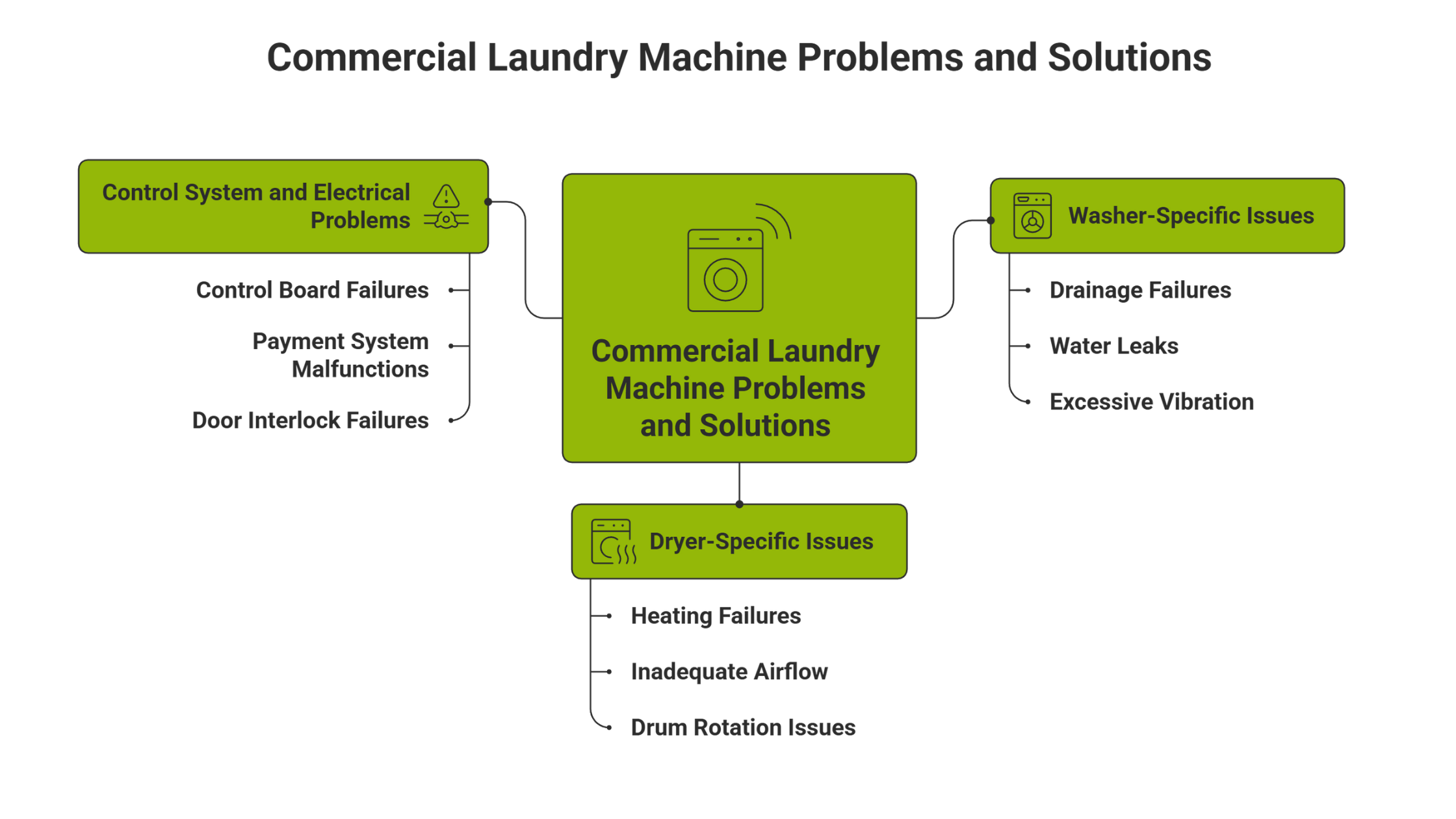

Common Commercial Laundry Machine Problems and Solutions

Understanding frequent failure patterns helps business owners recognize when to call for laundry equipment repair services.

Washer-Specific Issues

Drainage failures top the list of commercial washer problems. Clogged drain hoses, failed pumps, or obstructed filters prevent proper water evacuation, leaving clothes soaked and cycles incomplete. Our technicians clear blockages, replace worn pumps, and service drain valves to restore full drainage function.

Water leaks stem from deteriorated door gaskets, cracked hoses, or damaged pump seals. Machines refusing to fill indicate kinked inlet hoses, failed water valves, or supply pressure issues. Our commercial laundry machine service includes testing water delivery systems and replacing faulty valves to restore proper fill operation.

Excessive vibration during extraction results from unbalanced loads, worn shock absorbers, or damaged drum assemblies. These mechanical issues accelerate wear across the entire machine while creating noise disturbances.

Dryer-Specific Issues

Heating failures account for the majority of commercial dryer repair calls. Electric dryers lose heating when elements burn out, thermostats fail, or electrical connections corrode. Gas dryers stop heating when ignitors weaken, burners clog, or gas valves malfunction.

Clothes emerging damp despite completed cycles signal inadequate airflow from clogged lint traps, blocked exhaust ducts, or failing blowers. Lint accumulation doesn't just reduce efficiency. It creates serious fire hazards requiring immediate attention.

Drums refusing to rotate indicate broken belts, seized bearings, or motor failures. These mechanical breakdowns require component replacement and careful reassembly.

Control System and Electrical Problems

Modern commercial laundry equipment relies heavily on electronic controls vulnerable to moisture, power surges, and component fatigue. Control board failures manifest as non-responsive displays, erratic cycle behavior, or complete system shutdown.

Payment system malfunctions disrupt coin and card revenue collection. Electronic validators wear out, software glitches occur, and connectivity issues interrupt cashless payment processing.

Door interlock and safety switch failures prevent machines from starting or create mid-cycle shutdowns. These electrical safety devices wear from repeated use, requiring replacement to restore proper operation.

Our Commercial Laundry Repair Process

Real Clean Group follows structured protocols ensuring efficient diagnosis, quality repairs, and lasting results.

Initial Service Call and Diagnostics

Your repair process begins when you contact our team via phone at 720-391-4531 or through our service request page. We gather essential information about your equipment type, symptoms, and operational context to dispatch the right technician with appropriate parts.

On-site diagnostics involve systematic testing using manufacturer-specific procedures and diagnostic tools. Our technicians assess error codes, measure electrical values, inspect mechanical components, and test operational sequences. This thorough evaluation identifies root causes rather than just addressing symptoms.

We provide transparent cost estimates before beginning repairs, explaining the problem, required parts, labor involved, and expected completion timeline.

Repair Execution and Testing

Repairs proceed using factory-specified parts whenever possible. Real Clean Group maintains parts inventory for common components, enabling same-day fixes for many issues. Specialized parts ship quickly through our distributor networks, minimizing delays.

Our technicians follow manufacturer repair procedures and safety protocols throughout the work. Comprehensive testing follows every repair. We run complete cycles, verify proper operation across all functions, and confirm that error conditions clear.

Post-Repair Support and Documentation

You receive detailed documentation covering work performed, parts installed, and any recommendations for ongoing maintenance. Our team provides operation guidance when repairs involve new components or updated systems. Follow-up support remains available if questions arise or performance concerns develop.

Real Repair Success Stories

Healthcare Facility Prevents $15,400 Outsourcing Crisis

A Colorado hospital's primary washer failed during peak operations in 2024. Laundry outsourcing would have cost $1,100 per day, threatening $15,400 in expenses during the projected two-week repair timeline. Our technician diagnosed a failed drum bearing within 90 minutes, sourced the OEM component from local inventory, and completed repairs in 8 hours. We avoided the outsourcing crisis entirely.

Following this incident, the facility implemented our quarterly preventative maintenance program. Over the next year, breakdowns dropped by 70% and equipment outages were limited to under 12 hours annually. The hospital's $3,600 annual maintenance investment diverted over $20,000 in outsourcing costs while maintaining hygiene compliance and reducing linen losses.

Denver Hotel Saves $12,000 During Peak Season

A 200-room Denver hotel experienced washer-extractor failure during peak tourist season. With the machine processing 500 pounds of linens daily, downtime threatened guest services and forced emergency contingency planning. Our emergency response team arrived within 4 hours, diagnosed control board failure complicated by a worn door interlock, and completed repairs within the same business day.

The repair cost $850 versus $8,000 in commercial laundry outsourcing for peak-season pricing. More importantly, avoiding 48-hour downtime protected an estimated $12,000 in guest satisfaction costs (room compensation, negative reviews, and operational disruptions). The hotel subsequently enrolled in our preventative maintenance program, eliminating emergency repairs over the following 18 months.

Laundromat Cuts Annual Repairs 60% Through Equipment Upgrade

A Fort Collins laundromat struggled with outdated equipment generating frequent breakdowns costing $2,000–$8,000 annually per machine and causing 20–40 hours of downtime yearly. After the third major repair in six months, the owner consulted our equipment sales team about strategic replacement.

We recommended upgrading to modern Speed Queen machines, projecting reduced maintenance, improved efficiency, and enhanced customer experience. The facility saved 6,824 gallons of water monthly and $1,736 annually in utility costs alone. Revenue per square foot increased 20% within six months due to improved reliability and customer perception. Emergency repair costs dropped 60%, and the owner recovered the equipment investment within 36 months through combined savings and revenue growth.

Emergency vs. Scheduled Repair Services

Different operational demands require flexible service approaches matching your facility's specific needs.

24/7 Emergency Repair Service

Equipment failures don't respect business hours. Real Clean Group provides emergency commercial laundry repair service when critical breakdowns threaten your operations. Contact us immediately when safety hazards emerge, major revenue disruption occurs, or equipment failures impact customer commitments.

Emergency service prioritizes rapid response to assess situations quickly and implement temporary solutions when immediate permanent repairs aren't feasible. We maintain parts inventory and technician availability to handle urgent situations across our Colorado and Wyoming service area. For laundromats, downtime costs $50-$100 per hour in lost customer revenue, while hotels and healthcare facilities lose $100-$400 per hour.

Contact our office at 720-391-4531 to discuss your specific emergency repair needs and available response options. We'll work to minimize your downtime and get operations restored as quickly as safely possible.

Preventive Maintenance Programs

Scheduled commercial laundry maintenance proves far more cost-effective than reactive emergency repairs. Implementing IoT-enabled predictive maintenance platforms has reduced emergency repairs by 18-25% annually for franchise laundromats, translating to 36-60 hours of avoided downtime per location yearly.

Real Clean Group offers preventive maintenance programs tailored to your equipment type, usage intensity, and operational schedule. Regular maintenance visits include filter cleaning, hose inspection, seal evaluation, belt tension adjustment, and electrical connection tightening. Technicians identify wear patterns before components fail, allowing planned replacement during scheduled downtime rather than emergency breakdowns.

Preventive maintenance programs include priority scheduling, discounted service rates, and detailed equipment tracking. Facilities with scheduled maintenance programs have reduced major repair bills from $8,500 annually to below $4,500.

What to Expect: Repair Costs and Timelines

Understanding typical costs and completion timeframes helps you budget appropriately and plan around equipment downtime.

Factors Affecting Repair Costs

Equipment age and brand significantly influence repair expenses. Older machines often need increasingly expensive parts as availability decreases and wear accumulates across multiple systems. Premium brands like Speed Queen may have higher parts costs but often prove more economical long-term through superior durability.

Problem complexity determines labor requirements. Simple repairs like door latch replacement or hose swapping complete quickly with minimal cost. Complex issues involving control board diagnosis, motor replacement, or drum rebuilding require more technician time and specialized expertise.

Parts availability affects both cost and timing. Common components stock locally for immediate use at standard pricing. Specialized parts requiring manufacturer ordering cost more and extend repair timelines. Drain pump replacements range $350–$800, while motor repairs cost $700–$1,500 depending on unit size and complexity.

Service urgency impacts pricing. Emergency after-hours repairs command premium rates reflecting technician availability and response speed. Scheduled maintenance visits during regular business hours provide the most economical service option.

Typical Turnaround Times

Minor repairs addressing simple component failures typically complete within 2–4 hours when parts are readily available. These include sensor resets, seal replacements, and basic electrical fixes.

Intermediate repairs involving major component replacement require 1–2 business days. Motor swaps, pump installations, and control board replacements need careful disassembly, proper installation, and thorough testing.

Major overhauls involving drum assembly rebuilding, complete electrical system replacement, or extensive mechanical reconstruction can take several days to a week. These comprehensive repairs essentially restore equipment to like-new condition.

Emergency response timing depends on situation severity and technician availability. We prioritize critical failures affecting safety or causing major operational disruption, targeting same-day assessment for urgent calls.

Repair vs. Replacement: Making the Right Decision

Strategic equipment decisions balance immediate costs against long-term operational value. This framework helps you evaluate your options objectively.

The 20% Rule and Age Considerations

Commercial washers and dryers typically deliver 10–15 years of service life under proper maintenance. Equipment under five years old with minimal repair history usually justifies repair investment. Machines nearing or exceeding expected lifespan deserve careful evaluation before committing to expensive repairs.

When annual maintenance and repair costs exceed 20% of replacement cost, replacement becomes financially prudent. For equipment with a replacement cost of $4,500, this threshold sits at $900 annually. A $2,000 repair bill for a machine you could replace for $3,500 merits serious consideration, especially if the unit shows other wear indicators.

Cost-Benefit Comparison Framework

Repair Scenario: $800 pump repair on a 7-year-old $4,500 washer with 5+ years remaining life costs approximately $0.13 per expected remaining cycle.

Replacement Scenario: New $4,500 equipment with 12-year expected lifespan costs approximately $0.34 per cycle initially, but delivers energy savings of $1,008–$3,896 annually through improved efficiency.

Decision Factors:

Repair frequency: Multiple repairs within 12 months signal declining reliability

Downtime patterns: Increasing outages threaten operational consistency

Efficiency gap: Older equipment consumes significantly more utilities than modern alternatives

Technology benefits: IoT monitoring, programmable cycles, and contactless payments improve operations

When Replacement Makes Sense

Capacity considerations influence replacement timing. Undersized equipment creates operational bottlenecks and customer frustration. Laundromats upgraded with modern equipment document 15–30% higher revenue per square foot and 30–40% reduction in downtime compared to outdated facilities.

Technology advancements offer compelling upgrade incentives. Modern machines feature IoT monitoring, remote diagnostics, and advanced controls that improve operations and customer experience. For hotels, avoiding laundry delays protects $200-$500 per incident in room compensation costs.

Real Clean Group's equipment sales expertise helps you evaluate modern alternatives when replacement becomes appropriate, ensuring your investment aligns with operational demands and financial goals.

Why Choose Our Commercial Laundry Repair Service

Real Clean Group delivers commercial laundry equipment repair backed by verifiable credentials, local presence, and comprehensive capabilities.

Certified Technicians and Industry Credentials

Our technicians hold specific industry certifications demonstrating technical competency and regulatory compliance:

EPA Section 608 Technician Certification for safe refrigerant handling in equipment with refrigeration systems

NASTeC (National Appliance Service Technician Certification) from the Association of Home Appliance Manufacturers, covering diagnostic and repair competency for commercial laundry equipment

Manufacturer service training from Speed Queen, Maytag, and Huebsch for brand-specific diagnostics, service procedures, and warranty compliance

OSHA safety certifications covering electrical safety, lock-out/tag-out procedures, and workplace hazard prevention

These credentials ensure we handle your equipment according to engineering specifications and safety standards rather than generic approaches. Whether servicing Huebsch's Galaxy 600 Series, Speed Queen's Quantum Touch controls, or Maytag's Maxima systems, our team brings manufacturer-approved knowledge to every repair.

Local Presence and Response Capability

Real Clean Group's Colorado and Wyoming presence enables rapid response compared to distant national service chains. Local parts inventory, nearby technician dispatch, and regional familiarity combine to minimize your downtime.

We've completed over 500 projects across Colorado and Wyoming, serving hotels from Denver to Colorado Springs, healthcare facilities throughout the Front Range, and laundromats across both states. This hands-on experience across diverse industries provides practical problem-solving skills that improve diagnostic accuracy and repair efficiency.

Comprehensive Service Capabilities

Our capabilities extending beyond basic repairs differentiate Real Clean Group. Need replacement parts? Our parts supply operation ships quickly. Considering equipment upgrades? Our sales team helps evaluate options. Planning facility improvements? Our renovation services deliver complete solutions.

This full-service approach makes us your single commercial laundry partner rather than just another repair vendor, delivering millions in client savings and operational continuity over decades of combined industry experience.

How to Schedule Commercial Laundry Equipment Repair

Getting your equipment serviced requires just a simple contact with our team.

Call our office directly at 720-391-4531 to speak with our scheduling team. For sales inquiries, reach our sales team at 303-505-2509. Submit a service request through our website, providing details about your facility, equipment type, and the problems you're experiencing.

Email audrey@realclean.group with your repair needs, attaching any relevant photos or error code documentation. Visual information helps our technicians prepare appropriately and can expedite initial diagnostics.

When contacting us, have your equipment brand, model number, and approximate age available. Describe symptoms specifically. What's happening, when problems occur, and any error messages displayed.

For emergency situations requiring urgent attention, call rather than email to ensure immediate response. Our service area covers Colorado and Wyoming. We're locally based at 2045 S Valentia St, Unit 6, Denver, CO 80231.

Conclusion

Commercial laundry machines repair demands specialized expertise, rapid response, and deep understanding of how equipment failures impact your business operations. Real Clean Group delivers comprehensive commercial laundry repair service across Colorado and Wyoming, combining manufacturer-trained technicians, extensive parts inventory, and proven industry credentials to keep your laundry operations running efficiently.

Proactive maintenance prevents most equipment failures while catching problems early reduces repair costs dramatically. Whether you need emergency commercial washer repair, scheduled dryer servicing, or preventive maintenance programs, our team provides solutions tailored to hotels, healthcare facilities, salons, multi-housing properties, and laundromats.

Don't let equipment failures disrupt your operations and revenue.Contact Real Clean Group today to schedule service or discuss preventive maintenance programs protecting your laundry investment. Ready to upgrade aging equipment? Explore ourcommercial laundry equipment options designed for reliability, efficiency, and long-term performance.