How to Choose Hotel Laundry Equipment - Commercial Grade Solutions 2025

Table of Contents

Understanding Hotel Laundry Equipment Requirements in 2025

Getting your hotel laundry equipment right makes all the difference for smooth operations and happy guests in 2025. The right hotel laundry equipment is the fastest way to cut utility costs and speed linen turnaround. Real Clean Group has been helping businesses across various industries, including salons, healthcare facilities, veterinary clinics, hospitality, sports facilities, and government operations, optimize their laundry setups for decades. Whether you're looking to upgrade what you have or starting fresh with a new facility,understanding your equipment needs is where success begins.

TL;DR: Hotel Laundry Equipment That Cuts Costs and Speeds Turnaround

Right washer–dryer mix is set by room count, occupancy, and lbs/occupied room.

High-G extract + moisture sensors shorten dry times and protect linens.

Gas dryers usually cost ~½ per load vs. electric (when gas is available).

ENERGY STAR washers lower water/energy bills; look for strong MEF/WF ratings.

IoT monitoring + preventive service reduce downtime and surprise repairs.

Colorado advantage: local codes, rebates, and install expertise from Real Clean Group.

ROI: payback typically measured in labor saved, utility reduction, and longer linen life.

Real Clean Group specializes in helping hotels select, install, and maintain commercial laundry equipment that delivers real results.Contact their team to explore solutions tailored to your property's specific needs.

“Great stays start in the laundry room. With the right hotel laundry equipment, you protect linens, cut costs, and keep housekeeping on schedule.”

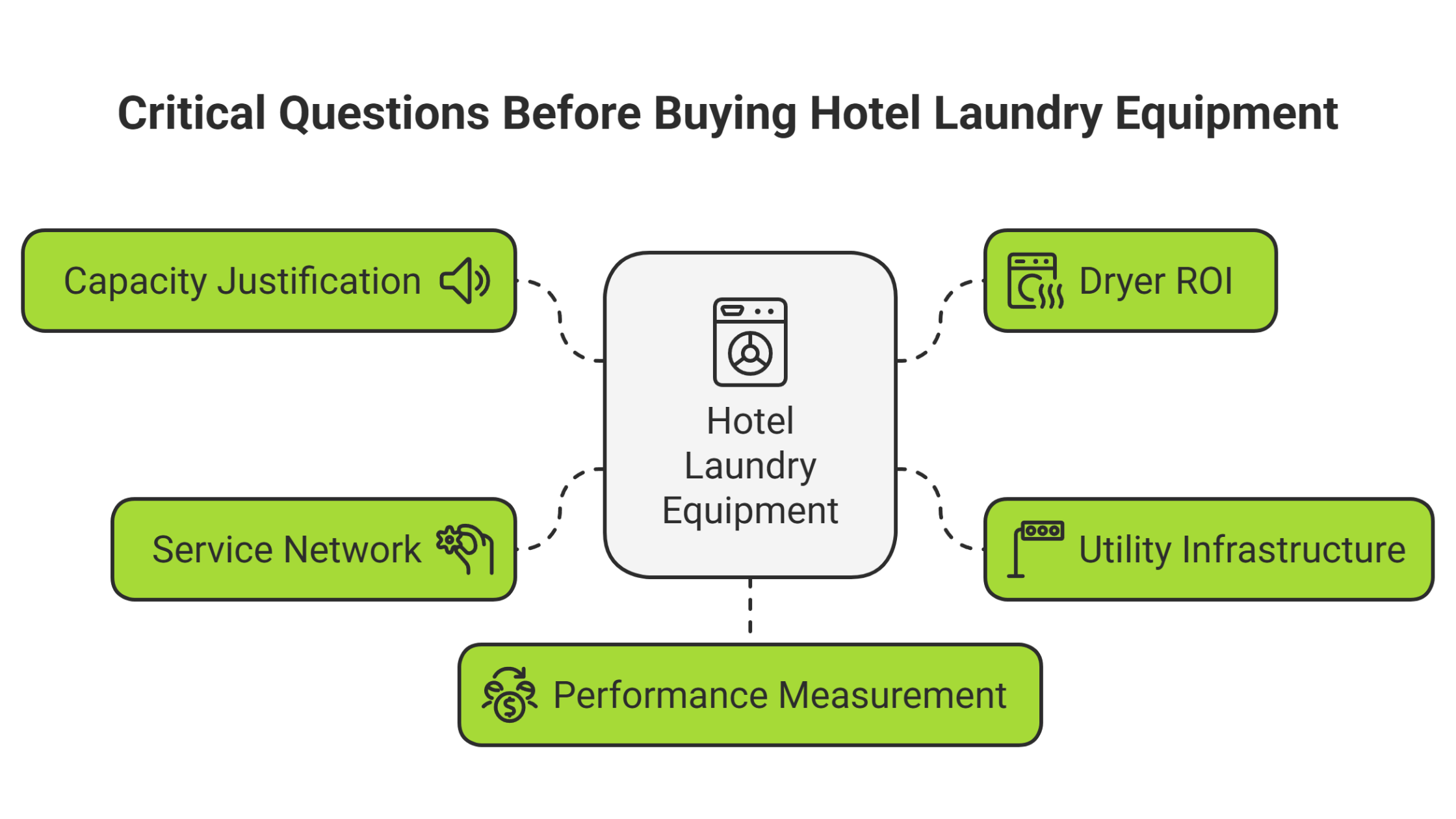

5 Critical Questions Before Buying Hotel Laundry Equipment

1. Does your daily volume justify the capacity? Take occupied rooms × pounds per room (10-28 lbs depending on service level) plus 20-30% for restaurants, spas, and pools. Size equipment to handle 1.2-1.5 times average volume for those busy peak periods.

2. Will gas or electric dryers deliver better ROI? Gas dryers cost roughly half per load to operate and complete cycles 30-50% faster, but they need higher upfront investment and gas infrastructure. Calculate your specific payback period based on local utility rates and processing volume.

3. Is your utility infrastructure adequate? Commercial equipment needs 208-240V three-phase power, 15-25 GPM water supply, and proper drainage capacity. Check upgrade costs before equipment purchase to avoid installation surprises.

4. What service network supports the equipment? Verify local technician availability, typical response times, and parts inventory. Equipment downtime during peak occupancy hits revenue and guest satisfaction directly.

5. How will you measure performance and ROI? IoT-enabled equipment gives you real-time analytics on cycle times, energy consumption, and maintenance needs. Set baseline costs per pound processed to track improvement.

Hotel Laundry Equipment and Capacity Planning

Operational Models and Volume Calculation

Sizing hotel laundry equipment starts with room count, occupancy, and pounds per occupied room. Large hotels and resorts typically run full-scale on-premise laundries (OPLs) to keep quality control tight and reduce per-load costs. They process bed linens, towels, restaurant tablecloths, spa robes, and staff uniforms. Extended-stay hotels often add self-service guest laundries as revenue-generating amenities with minimal staffing needs.

Calculate daily volume using room count multiplied by occupancy and pounds per occupied room (PPOR). Budget motels process around 10 lbs per room daily, mid-range hotels handle 12 lbs, full-service properties manage 14 lbs, and luxury hotels process 16-18 lbs. A 150-room full-service hotel at 75% occupancy handles roughly 1,575 lbs daily (150 × 0.75 × 14). Hotels with restaurants, spas, or pools should add 20-30% to base calculations.

Size equipment for peak season volumes, not annual averages. Calculate hourly throughput by dividing total daily volume by available processing hours. A hotel processing 2,000 lbs daily across a 10-hour shift needs 200 lbs per hour throughput. If washers complete cycles in 40 minutes (1.5 loads per hour) with 50 lb capacities, each machine processes 75 lbs per hour, requiring at least three washers to maintain pace.

Market Trends Driving Equipment Selection

The hospitality laundry sector saw major technological transformation through 2024-2025. The hotel laundry services market is projected to grow from $14.1 billion in 2025 to $20.5 billion by 2035, reflecting rising occupancy rates, tourism comeback, and increasing guest expectations for cleanliness.

Integration of IoT-enabled machines and automated laundry systems rapidly increased, with hotels reporting better operational efficiency and shorter turnaround times. Modern equipment incorporates IoT platforms letting facility managers monitor machine status remotely with real-time diagnostics, cycle completion alerts, and remote troubleshooting capabilities. These advances dramatically improve workflow and minimize downtime during peak occupancy periods.

Sustainability has become a major purchasing factor. There's a strong shift toward eco-friendly laundry practices, including biodegradable detergents, water-saving technologies, and energy-efficient machines. Artificial intelligence drives predictive maintenance systems that monitor component wear and diagnose issues before failures occur, particularly valuable for high-throughput hotel environments.

Essential Commercial Washers and Dryers for Hotels

High-Performance Washing Equipment

Modern hotel laundry equipment favors high-G extract washers to shorten drying times and protect linens. Commercial front-load washers dominate hotel laundry operations because they're more efficient and gentler on fabrics. These machines extract more water during the spin cycle, which cuts drying time and energy consumption significantly. Front-load designs allow stacking configurations and use less water per load, with programmable controls and multiple temperature settings for different fabric types.

ENERGY STAR certification identifies washers that deliver serious utility savings. The Modified Energy Factor (MEF) measures overall energy efficiency, with ENERGY STAR requiring a minimum MEF of 2.2 for commercial models. Water Factor (WF) represents water consumption efficiency, with a maximum WF of 4.0 allowed for certified commercial washers. Lower numbers mean better efficiency.

Large hotel chains with daily volumes exceeding 2,000 lbs often install tunnel washing systems. These continuous batch washers move laundry through multiple chambers performing specific functions, delivering unmatched throughput and consistency. Barrier washers benefit healthcare-adjacent hospitality facilities by preventing cross-contamination between soiled and clean laundry areas through separate loading and unloading doors.

Commercial Dryer Selection and Optimization

Dryer selection must match your hotel laundry equipment washer capacity and throughput goals. Commercial tumble dryers must match washer capacity to maintain efficient workflow. Most hotels install dryers with 1.5-2 times washer capacity to account for longer drying cycles. Advanced models incorporate moisture sensors that automatically adjust drying time based on actual fabric dampness, preventing over-drying that damages linens while eliminating energy waste.

Gas commercial dryers generally offer superior energy efficiency and lower operating costs compared to electric models. Gas dryers produce hotter, more immediate heat, resulting in roughly 20-35% lower energy usage per load. The cost to dry a load in a gas dryer typically runs about half that of an electric dryer thanks to lower gas prices. Gas dryers complete typical hotel loads 30-50% faster than electric models, often under 40 minutes compared to 55-70 minutes.

However, gas dryers carry higher upfront costs, typically $300-$500 more per unit, and need professional gas line installation. Electric dryers remain competitive where gas infrastructure isn't available or when building codes restrict gas appliances, with simpler maintenance requirements and lower installation complexity.

Stack dryers revolutionize space planning for urban hotels with limited square footage. Vertical stacking configurations let facilities double laundry processing capacity without expanding floor space. Leading commercial stack dryers offer capacities up to 45 lbs per drum, with typical units measuring just 27 inches wide by 74 inches high by 29.5 inches deep.

Smart Technology and Automation Systems

IoT-Enabled Monitoring and Predictive Maintenance

Modern commercial laundry equipment integrates with IoT platforms providing unprecedented operational visibility. Facility managers can access dashboards showing machine status, cycle times, temperature data, and water usage from any internet-connected device. Software systems generate detailed productivity reports revealing cycle durations, machine idle times, load counts, and efficiency metrics.

Analytics expose opportunities to consolidate operations during low-occupancy periods. Hotels can shift laundry processing to off-peak utility hours when electricity rates drop, reducing energy expenses without compromising service levels. Real Clean Group's experience optimizing laundry operations across healthcare, veterinary, and salon environments brings infection control and efficiency insights that elevate hospitality laundry standards.

Advanced equipment uses artificial intelligence and sensors to predict maintenance needs by monitoring component wear patterns. Systems track vibration levels, bearing temperatures, motor performance, and other indicators signaling developing problems. Real-time monitoring reduces unexpected breakdowns and extends equipment lifespan through proactive service, especially critical for high-throughput hotel environments where downtime directly impacts guest services.

Real Clean Group's maintenance programs leverage smart technologies to deliver preventive care keeping equipment running at peak efficiency. Their certified technicians respond to automated alerts before minor issues escalate into costly failures. Networked hotel laundry equipment plus preventive service keeps uptime, and guest scores, high.

Remote Management and Integration

Staff can check machine availability, receive cycle completion notifications, and adjust settings through dedicated mobile applications. This connectivity eliminates trips to the laundry room to check load status, allowing employees to multitask more effectively. Some systems allow guests to check washer and dryer availability from their rooms, reducing frustration and improving the self-service experience.

IoT platforms monitor energy consumption at the machine level, providing granular data about utility costs. Automated dosing systems ensure only required detergent, fabric softener, and bleach amounts are dispensed based on load characteristics, reducing operating costs and environmental impact while maintaining consistent results.

Leading hospitality technology platforms now support integration with laundry equipment management systems. This connectivity allows hotels to coordinate laundry operations with housekeeping schedules, guest checkout times, and occupancy forecasts. When the property management system shows high checkout volumes scheduled, the laundry system automatically adjusts schedules to ensure adequate clean linen inventory.

Cost Analysis and ROI: Real Hotel Outcomes

Documented Case Studies and Financial Performance

Recent hotel equipment upgrades show substantial, measurable returns. The Omni Charlotte Hotel achieved a 22% reduction in year-over-year laundry operational costs with annual utility savings reaching $19,000 after installing high-capacity ENERGY STAR washers and moisture-sensing dryers. Water and energy costs dropped by 30%, with 20-month payback on equipment investment. The property cut average cycle times by 18 minutes per load and extended linen replacement cycles by 15%.

The Hyatt Regency Vancouver upgraded to IoT-integrated equipment, with real-time analytics and predictive maintenance cutting downtime by 48% and improving cycle completion rates to 98%. Utility bills dropped 25% through dynamic energy management via IoT sensors connected to city grid pricing, with 24-month ROI on the Smart Laundry System investment.

The Marriott Marquis Houston implemented high G-force extraction washers, trimming labor costs by 17% due to reduced drying times and improved workflow. Energy costs dropped 21% with 18-month payback, while machine idle time decreased and staff productivity increased with load turnover boosting by 1.5x.

Operating Cost Components and Efficiency Gains

Utilities typically account for 8-10% of operating costs for in-house hotel laundry operations, with significant expenses tied to heating water and powering dryers. Modern washers with load sensing and variable water levels use only the water necessary for each specific load, reducing water consumption by 30-40% compared to older equipment. High-spin extraction speeds remove more moisture during wash cycles, reducing dryer energy requirements and cycle times.

Labor typically represents about 50% of total operating costs for in-house operations. According to industry data, roughly 70% of laundries report difficulties finding and keeping skilled staff, making automation increasingly valuable. Automated detergent dispensers eliminate manual measuring while ensuring consistent results, moisture sensors in dryers prevent over-drying that requires re-processing, and rapid cycle times increase pounds processed per labor hour.

The Fairmont Scottsdale Princess extended fabric life by 20% through on-premise laundry retrofit, reducing linen replacement expenses over three years. In-house laundry dropped overall expenses 27% versus previous outsourcing, with 16-month payback for new equipment and buildout. Turnaround times for linens improved with rooms processed and refreshed up to 30% faster on average.

Equipment Investment and Financing Options

Commercial laundry equipment costs typically range from $2,000 to $15,000 per machine depending on capacity, features, and brand. Commercial washers span $1,500 to $15,000 each, while dryers run $1,000 to $7,000, with mid-size machines commonly priced between $2,000 and $4,500.

Leasing offers lower upfront costs with monthly payments typically ranging from $100 to $300 per machine based on contract length and specifications. Many lease agreements include maintenance service, reducing unexpected repair costs and simplifying budget planning. Purchasing equipment outright provides full ownership and potential tax advantages through Section 179, which allows immediate expensing up to federal limits, enabling hotels to deduct the full purchase price in the first year.

The Hilton Garden Inn multifunctional automation pilot achieved equipment downtime consistently under 2% per month, with wash quality rated at 95%+ customer satisfaction. Combined automated sorting/folding machines and smart washers/dryers yielded labor savings of 23%, with 15-month payback following full automation integration.

Common Equipment Challenges and Solutions

Operational Pain Points Hotels Face

About 88% of commercial laundries cite rising operational costs as their top concern, with escalating utility bills, water costs, and maintenance expenses squeezing profit margins. Facilities implementing cost-control measures like energy-efficient upgrades or preventive maintenance report 20-30% reductions in operational expenses, highlighting the financial impact of doing nothing.

Aging or outdated equipment represents another critical challenge. Older machines are less energy-efficient, need more maintenance, and have higher failure rates. This leads to slower cycle times, increased water and energy consumption, and frequent breakdowns that delay laundry processing and impact room turnovers. Unplanned downtime forces hotels to outsource laundry or rush orders, significantly increasing costs.

Inventory management and quality control remain ongoing challenges. Poor inventory tracking results in shortages forcing use of subpar linens, overstocking that ties up capital, or loss and theft of items. Quality issues like poorly washed or damaged linens lead directly to guest dissatisfaction and negative reviews, with reputational damage and potential lost repeat business.

Preventive Maintenance and Service Support

Daily maintenance includes cleaning lint filters before each use, wiping down machine surfaces, and checking for visible leaks or unusual noises. Weekly tasks involve inspecting hoses and water inlets for wear or cracks and ensuring drains remain free from blockages. Monthly maintenance includes examining belts and bearings for wear, checking heating elements and airflow in dryers, and lubricating components per manufacturer guidelines.

Hotels should schedule quarterly or semi-annual professional servicing where certified technicians conduct thorough inspections, check electrical systems, calibrate controls, assess water pressure and drainage, and replace or adjust worn parts. This proactive approach prevents failures and ensures compliance with safety standards.

Real Clean Group offers comprehensive service programs including regular maintenance, emergency repairs, technical support, and replacement parts supply. Their simplified systems and staff training help hotels maintain equipment properly between professional service visits, maximizing uptime and performance. Their equipment selection, delivery, and installation services include complete onboarding to ensure smooth transitions.

Choosing Your Equipment Partner

Service Network and Support Evaluation

Local commercial laundry suppliers often provide personalized service, faster response times, and relationships with on-site staff. They understand regional building codes, utility rate structures, and climate considerations affecting equipment selection. National service networks offer broader resources including proprietary technology platforms, extensive parts inventories, and standardized procedures ensuring consistent service quality.

Hotels should evaluate service network coverage carefully. The best equipment becomes worthless if qualified technicians can't reach your property quickly when problems arise. Ask about average response times, technician certification levels, and parts availability before making commitments. Comprehensive training ensures staff can operate equipment properly and perform basic maintenance tasks.

Real Clean Group delivers staff training through simplified systems like automatic detergent dispensers and clear operational guidelines. Their project management expertise and relationships with equipment manufacturers, utility companies, and contractors streamline implementation from initial assessment through full operation. Real Clean Group's renovation services help hotels redesign existing laundry spaces or plan new facilities that maximize efficiency and meet all building codes.

Implementation and Installation Considerations

Planning a laundry facility upgrade or new installation typically spans 4-8 months from initial assessment through full operation. The timeline includes needs assessment (2-4 weeks), equipment selection and vendor negotiations (3-4 weeks), utility infrastructure upgrades if needed (4-8 weeks), equipment delivery and installation (2-3 weeks), testing and staff training (1-2 weeks), and optimization period (ongoing).

Commercial laundry equipment draws substantial power, often requiring dedicated electrical circuits and upgraded service panels. Large washers and dryers typically need 208-240V three-phase power instead of standard 110V circuits. Gas-fired dryers require professional installation of gas supply lines sized to deliver adequate BTU input. Commercial washers need hot and cold water supply lines sized for high flow rates, with most machines requiring 15-25 gallons per minute supply capacity.

Hotels should begin planning at least six months before anticipated need, particularly if building code compliance issues require permits or structural modifications. Efficient laundry layouts separate soiled and clean processing zones to prevent cross-contamination, designing traffic flows that move laundry linearly from receiving through sorting, washing, drying, folding, and storage without backtracking or congestion.

Conclusion: Optimizing Your Hotel Laundry Investment

Selecting the right hotel laundry equipment in 2025 requires balancing capacity needs, energy efficiency, technology integration, and budget considerations. Modern commercial laundry equipment for hotels delivers measurable ROI through reduced utility costs, lower labor requirements, and enhanced operational efficiency. Hotels implementing best practices achieve significant cost reductions while delivering superior guest experiences.

Real Clean Group brings decades of expertise helping hospitality operators across multiple industries including salons, healthcare facilities, veterinary clinics, sports facilities, and government operations optimize their commercial laundry operations. Their comprehensive approach encompasses equipment selection, installation, ongoing maintenance, and staff training to ensure long-term success. Whether you're operating a boutique property in Colorado or managing a large chain hotel, the right equipment partner makes the difference between laundry that simply functions and operations that deliver competitive advantages.

Ready to upgrade your hotel laundry equipment for 2025? Contact Real Clean Group today to discuss your specific needs and discover how modern commercial laundry solutions can improve your operations, reduce costs, and enhance guest satisfaction. Their team of certified technicians and equipment specialists will help you build a laundry facility that meets today's demands while preparing for tomorrow's opportunities.